Content

- 1 Understanding Circlips and Their Function

- 2 What Are External Circlips?

- 3 What Are Internal Circlips?

- 4 Key Differences Between External and Internal Circlips

- 5 When to Use External Circlips

- 6 When to Use Internal Circlips

- 7 Which is Better for Your Application?

- 8 Conclusion: Choosing the Right Circlip for Optimal Performance

Understanding Circlips and Their Function

Circlips are essential mechanical fasteners used to secure components in place within a housing or on a shaft. They come in two primary types: external circlips and internal circlips. Both are designed to prevent displacement and ensure secure fitment, but they are used in different applications depending on the design and function of the assembly. In this article, we will compare external circlips with internal circlips, discussing their key differences, advantages, and which type is best suited for your specific mechanical application.

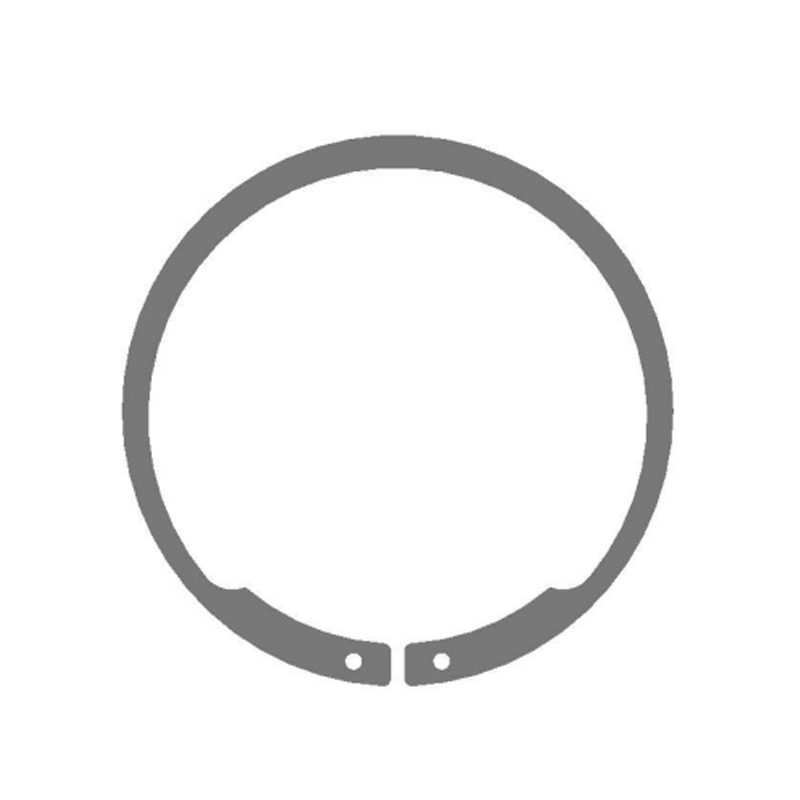

What Are External Circlips?

External circlips, also known as snap rings, are designed to fit into grooves on the outside of a shaft or cylindrical component. These circlips apply an outward force against the housing or shaft, preventing components from moving or becoming displaced. External circlips are commonly used to secure bearings, gears, and other parts in mechanical assemblies where the fastener must hold the part in place on the exterior of the shaft or housing.

What Are Internal Circlips?

Internal circlips, in contrast, are installed in grooves within a bore or housing. Unlike external circlips, which apply pressure outward, internal circlips exert an inward force to secure components in place within the housing. These fasteners are typically used when securing parts such as shafts, pins, or other internal components inside a cylindrical housing. Internal circlips are most commonly found in applications where space limitations or the design of the assembly require the fastener to sit inside the component.

Key Differences Between External and Internal Circlips

While both external and internal circlips perform similar functions, they have distinct characteristics that make each type more suitable for specific applications. Below are the key differences:

- Installation Location: External circlips are installed on the outside of a shaft or component, while internal circlips are inserted into grooves inside the bore or housing.

- Load Direction: External circlips apply an outward pressure to hold components in place, whereas internal circlips exert an inward pressure to secure internal parts within the housing.

- Usage: External circlips are commonly used in applications where the component is mounted on the outside of a shaft or axle, while internal circlips are ideal for securing parts inside a bore or housing.

- Design and Space Constraints: External circlips tend to be larger and are better suited for applications with more space for installation. Internal circlips, on the other hand, are more compact and used in spaces where internal components need to be secured.

- Strength and Durability: Both external and internal circlips are made from high-strength materials, such as carbon steel or stainless steel, offering durability and resistance to wear. However, the design of the groove and the way the load is applied can affect the strength required for the circlip to perform effectively.

When to Use External Circlips

External circlips are typically the preferred choice in applications where the fastener needs to secure parts on the outside of a shaft, pin, or other cylindrical components. Here are some examples of when to use external circlips:

- Automotive Applications: External circlips are commonly used in automotive applications, such as securing axles, wheel hubs, and transmission gears.

- Industrial Machinery: External circlips are ideal for securing bearings, pulleys, or sprockets on shafts in industrial machinery where external load-bearing capacity is required.

- Heavy Equipment: In heavy equipment and construction machinery, external circlips are used to secure large, heavy-duty components in place on rotating shafts and axles.

When to Use Internal Circlips

Internal circlips are ideal for applications where the fastener needs to secure components inside a housing or bore. These applications typically require the circlip to fit within confined spaces or to secure parts that need to be kept inside a cylindrical structure. Some examples of when to use internal circlips include:

- Small Engine Parts: Internal circlips are used in small engines to secure parts like pistons and connecting rods inside the engine block or cylinder bore.

- Bearings and Bushings: Internal circlips are frequently used in machinery that requires bearings or bushings to be held securely in place within a housing or casing.

- Precise Equipment: Internal circlips are ideal for high-precision equipment, such as pumps, gearboxes, or hydraulic systems, where components must remain fixed within a confined space.

Which is Better for Your Application?

Choosing between external and internal circlips depends on several factors, such as the space available in the assembly, the direction of the load, and the type of components being secured. In general, external circlips are better suited for applications with larger space and when securing components that need to be held on the outside of a shaft or housing. Internal circlips are preferred in compact or confined spaces where parts need to be secured within a bore or casing.

When selecting the right circlip, consider the following:

- Component Location: Choose external circlips if the components are mounted on the outside of a shaft, and internal circlips if the components need to be secured within a housing or bore.

- Space Availability: For applications with tight or confined spaces, internal circlips are the best choice, while external circlips are better for applications with more space.

- Load Type: Consider the type of load and pressure the circlip will be subjected to. External circlips are ideal for high-load applications on rotating parts, while internal circlips are more suited to holding components inside static or rotating housings.

Conclusion: Choosing the Right Circlip for Optimal Performance

Both external and internal circlips play vital roles in mechanical assemblies by preventing component displacement and ensuring secure fitment. The choice between the two depends largely on the design of your assembly, the location of the components, and the space constraints within the system. By understanding the key differences and selecting the appropriate circlip for your application, you can enhance the performance, durability, and safety of your mechanical systems. Whether you're working with automotive parts, industrial machinery, or precision equipment, the right circlip ensures that your components stay securely in place, minimizing the risk of failure and maximizing the longevity of your assembly.