Circlips, also known as retaining rings or snap rings, are essential components used to secure parts on a shaft or inside a housing. Despite their small size, they play a critical role in keeping assemblies in place, especially in mechanical systems with rotating or sliding parts. Among the most common types are internal circlips and external circlips. While they serve similar purposes—preventing lateral movement of components—their design, function, and installation are notably different.

In this article, we’ll explore the key differences between internal and external circlips, including their structure, application, installation methods, and how to choose the right type for your needs.

Content

What Are Circlips?

Circlips are semi-flexible metal rings that fit into machined grooves in a bore (hole) or on a shaft. They act as mechanical fasteners, keeping components from sliding off or shifting along the axis. Circlips are typically made from spring steel or stainless steel, offering the elasticity and strength needed for repeated assembly and disassembly.

Circlips come in various designs, but the two primary types are:

Internal circlips – fit into a groove inside a bore or housing

External circlips – fit into a groove on the outside of a shaft

1. Design and Structure

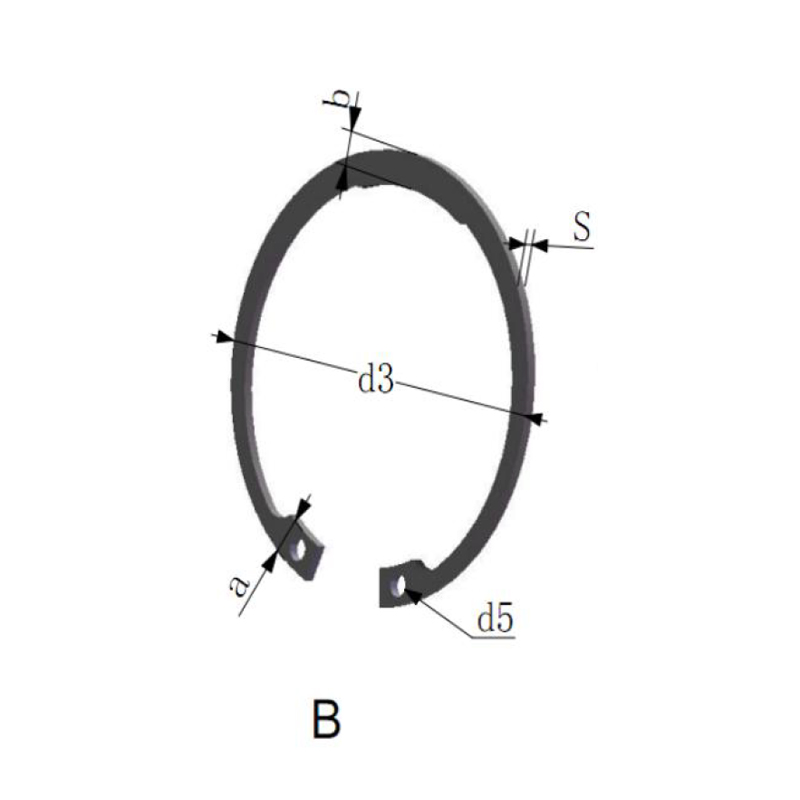

Internal Circlips

Shaped to fit within the internal diameter of a cylindrical bore or housing

Ends are usually equipped with small holes or lugs for circlip pliers

Compress when installed, applying outward pressure to hold themselves in place

External Circlips

Designed to wrap around the external diameter of a shaft

Feature open ends that expand during installation

Contract into the shaft groove, applying inward pressure to stay seated

2. Installation and Removal

Both types of circlips require special pliers, known as circlip pliers or snap ring pliers, with tips that fit into the holes on the ends of the circlip.

Installing Internal Circlips:

Use internal circlip pliers with outward-opening tips

Insert the tips into the circlip holes, compress the ring, and insert it into the internal groove of the bore

Release to allow the circlip to snap into place

Installing External Circlips:

Use external circlip pliers with inward-closing tips

Insert the tips, expand the circlip, and slide it over the shaft into the groove

Release to seat the ring snugly in position

Removal is simply the reverse of installation, using the same type of pliers.

3. Applications

The primary distinction in applications depends on whether the component needs to be restrained inside a hole or on a shaft.

Internal Circlips Are Used To:

Prevent components from sliding out of bores or cylindrical housings

Hold bearings, sleeves, or bushings inside a hole

Common in automotive transmissions, hydraulic cylinders, and gear housings

External Circlips Are Used To:

Keep parts from sliding off a rotating shaft or axle

Secure gears, pulleys, or bearings in place

Often found in electric motors, drive shafts, and machine tool assemblies

4. Advantages and Considerations

| Feature | Internal Circlips | External Circlips |

| Mounting Location | Inside a bore or housing | Around a shaft |

| Installation Force | Compressed during installation | Expanded during installation |

| Load Direction | Resists force pushing outward | Resists force pushing inward |

| Common Use | Housing retention | Shaft retention |

Internal Circlip Pros:

Protects components inside sealed environments

Reduced risk of external contamination

Neat, flush finish with fewer protruding parts

External Circlip Pros:

Easy to inspect and replace

Strong radial grip on rotating shafts

Often easier to install in open systems

5. Material and Coatings

Both types are typically made from:

Carbon spring steel – durable, with high tensile strength

Stainless steel – corrosion-resistant for marine or food-grade environments

Phosphate or black oxide coatings – reduce friction and resist corrosion

Zinc-plated options – for added rust resistance and visual contrast

Some applications may require heat-treated circlips for higher load resistance or non-magnetic alloys in sensitive environments.

6. Standards and Sizes

Circlips follow standardized dimensions according to international standards:

DIN 472 – Internal circlips for bores

DIN 471 – External circlips for shafts

ANSI/ASME B18.27 – North American snap ring standard

Always choose the correct size based on the groove diameter and ring thickness. Improper sizing can lead to circlip failure, which may cause machinery damage or safety hazards.

7. Choosing Between Internal and External Circlips

When selecting a circlip, ask the following:

Is the component located inside a housing or on a shaft?

What is the expected axial load direction?

How much assembly space is available?

What are the environmental conditions (humidity, temperature, chemicals)?

Is regular maintenance or disassembly required?

For projects involving both internal and external connections, it is common to use both types of circlips together, each serving a specific retention function.

Conclusion

Although similar in concept, internal and external circlips serve distinct purposes and are tailored to different parts of mechanical assemblies. Understanding the difference between them—how they install, where they fit, and how they function—is crucial to ensuring safe, secure, and effective machinery design.

Whether you’re working on industrial equipment, automotive systems, or precision tools, selecting the correct circlip type and size is key to maintaining performance and minimizing wear over time. When in doubt, refer to industry standards or consult a manufacturer to find the right fit for your application.

By mastering these small but mighty components, engineers and technicians can ensure that rotating parts stay secure, moving components remain aligned, and mechanical systems operate safely and smoothly.