Content

Introduction to Internal Circlips

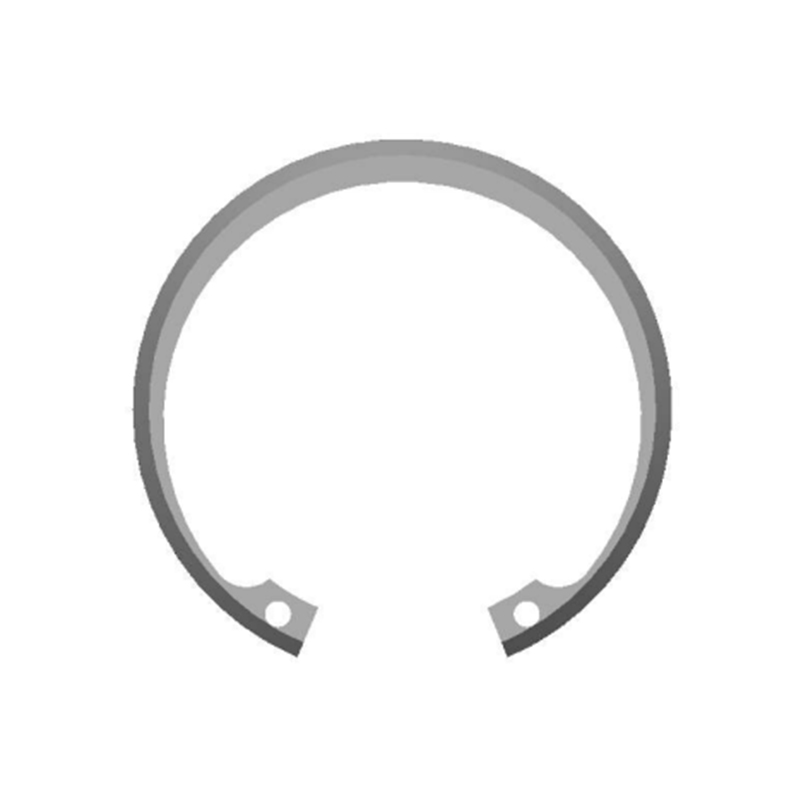

Internal circlips, also known as retaining rings, are widely used components in mechanical assemblies for securing shafts, bearings, and other cylindrical parts. One of their main advantages is the ability to provide quick installation and removal, which saves time and reduces labor costs during assembly or maintenance processes. Unlike other fastening solutions, circlips do not require complex tools or extensive procedures, making them highly practical for industrial applications.

Design Features Supporting Quick Installation

The design of internal circlips includes a flexible, semi-circular ring with open ends. This structure allows them to be easily compressed or expanded with the right tool, enabling fast placement into the groove of a shaft or bore. The flexibility also ensures that the circlip snaps securely into place, eliminating the need for additional fasteners or adhesives. These characteristics make internal circlips particularly effective in high-volume production environments where time efficiency is critical.

Tool Compatibility

- Special circlip pliers allow precise compression and expansion without deforming the ring

- Standard hand tools can be used for smaller or less critical applications

- Reduced risk of damaging surrounding components during installation

- Facilitates installation in confined spaces due to compact tool design

Advantages in Removal and Maintenance

Internal circlips also simplify the removal process, which is essential for maintenance or replacement of parts. By using circlip pliers or similar tools, technicians can quickly release the ring without disturbing adjacent components. This ease of removal significantly reduces downtime in industrial operations, allowing for faster repairs and more efficient maintenance schedules.

Practical Benefits of Quick Removal

- Minimizes labor time required for disassembly

- Reduces risk of component damage during removal

- Enables rapid inspection and replacement of worn parts

- Supports preventive maintenance by simplifying part access

Time and Cost Efficiency

The combined ease of installation and removal of internal circlips translates into significant time and cost savings. In production lines, this efficiency allows for faster assembly cycles and higher throughput. For maintenance teams, the reduced complexity of circlip handling lowers labor costs and improves operational reliability. Overall, the use of internal circlips supports both productivity and safety in industrial settings.

Comparison Table of Retaining Solutions

| Fastening Type | Ease of Installation | Ease of Removal | Tool Requirement |

| Internal Circlip | High | High | Circlip Pliers |

| Bolts & Nuts | Moderate | Moderate | Wrenches |

| Set Screws | Low | Low | Hex Keys |

Conclusion

Internal circlips offer a clear advantage in terms of quick installation and removal, making them ideal for both assembly line production and maintenance-intensive operations. Their flexible design, compatibility with specialized tools, and ease of handling contribute to time efficiency, cost savings, and safer mechanical assemblies. Choosing internal circlips ensures reliable retention of components while reducing operational complexity in industrial applications.