Circlips, also known as retaining rings or snap rings, are simple yet essential components used in mechanical engineering to hold parts securely in place. They fit into grooves on shafts or inside bores, preventing axial movement and maintaining the correct position of components such as bearings, washers, and pins. Two primary types exist: internal circlips and external circlips. Though they may look similar at first glance, they serve different functions and are designed for different applications.

What Is a Circlip?

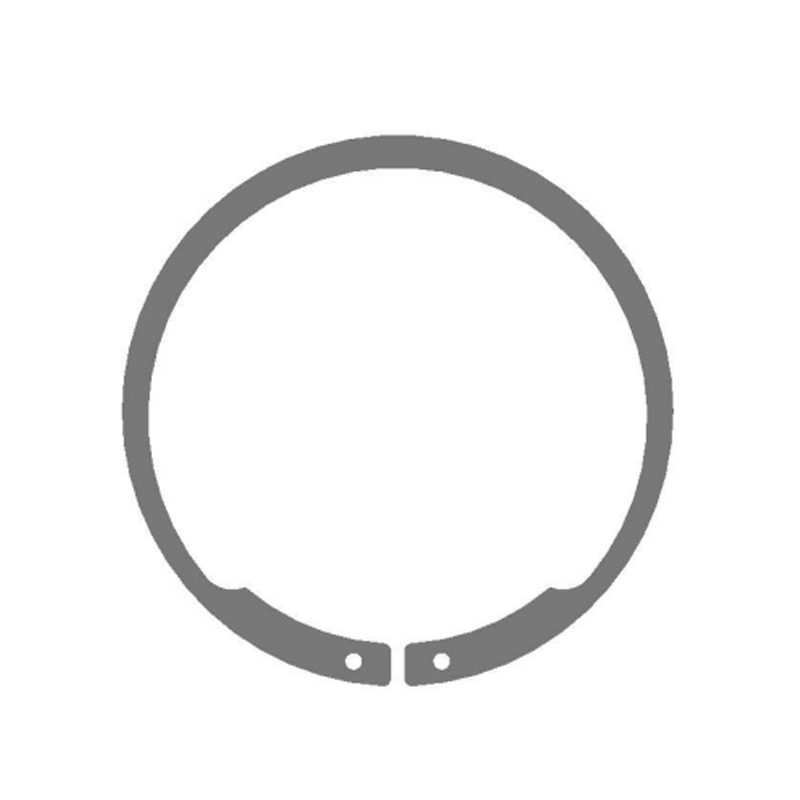

A circlip is a semi-flexible ring with open ends, typically made of spring steel or stainless steel. When installed into a groove, it snaps into place and acts as a mechanical stop. Circlips are used to secure parts on shafts or inside housings, preventing lateral movement without the need for additional fasteners.

Circlips come in two main types:

Internal Circlips: Designed to fit into a groove inside a bore or housing.

External Circlips: Designed to fit into a groove on the exterior of a shaft.

Both types are vital in maintaining the structural integrity and functionality of mechanical systems.

What Is an Internal Circlip?

An internal circlip is installed inside a cylindrical bore or housing. It fits into a pre-machined groove on the inner wall and is used to retain components such as bearings or bushings within the housing, preventing them from moving outward.

Features of Internal Circlips:

Installed inside a hole, bore, or housing.

Expandable to fit into the groove during installation.

Once in place, it contracts and applies outward pressure.

Commonly used in applications where components must be retained inside a casing.

Common Applications:

Hydraulic and pneumatic cylinders (to retain piston assemblies).

Gear housings.

Valve assemblies.

Electric motor housings.

Automotive components.

In hydraulic cylinders, internal circlips can be used to retain piston seals or guide rings within the bore, ensuring stable and precise linear movement.

What Is an External Circlip?

An external circlip is mounted on the outside diameter of a shaft. It fits into a groove machined around the shaft and acts as a shoulder to hold components such as bearings, gears, or spacers in position along the shaft axis.

Features of External Circlips:

Installed onto shafts or rods.

Contracted during installation and then expands into the groove.

Applies inward pressure against the shaft groove.

Prevents axial movement of components mounted on the shaft.

Common Applications:

Shafts in gearboxes and transmissions.

Hydraulic cylinder rods (e.g., to retain rod-end parts or sealing arrangements).

Electric motor rotors.

Power tools.

Aerospace and automotive drivetrains.

In hydraulic cylinder assemblies, external circlips are often used on the piston rod to secure end fittings, bearing components, or seals that must remain in place during linear actuation.

Key Differences Between Internal and External Circlips

| Feature | Internal Circlip | External Circlip |

| Installation Location | Inside a housing, bore, or hole | On the outside of a shaft |

| Action on Installation | Expands to fit the groove | Contracts to fit the groove |

| Axial Retention | Prevents outward movement of components | Prevents inward movement of components |

| Tool Required | Internal circlip pliers (expanding) | External circlip pliers (contracting) |

| Groove Type | Groove machined inside a bore | Groove machined on a shaft |

| Common Applications | Housings, cylinder bores, casings | Shafts, rods, external rotating elements |

Material and Strength Considerations

Both types of circlips are generally made from high-strength materials such as:

Spring steel for general-purpose, high-resilience applications.

Stainless steel for corrosion resistance in outdoor or fluid-based environments.

Phosphor bronze or other alloys for electrical conductivity or special mechanical properties.

In high-load or high-speed applications—such as in hydraulic systems—the circlips must be chosen with regard to fatigue resistance, thermal expansion, and compatibility with lubricants or hydraulic fluids.

Circlips in Hydraulic Cylinders

In hydraulic cylinders, both internal and external circlips play critical roles. Internal circlips are often used to hold the piston within the bore, keeping seals, spacers, and guide rings properly aligned. External circlips may be used to secure components on the rod end or to anchor the cylinder in its housing.

Proper use of circlips in hydraulic systems ensures:

Accurate axial positioning of moving parts.

Prevention of component dislodgement under high pressure.

Minimal wear due to correct alignment.

Easy assembly and disassembly during maintenance.

Installation and Removal Tips

Use the Right Pliers: Special circlip pliers are designed with pointed tips that fit into the circlip’s eyelets.

For internal circlips: use pliers that expand the ring.

For external circlips: use pliers that compress the ring.

Don’t Overstretch or Overcompress: Excessive force can permanently deform the circlip or weaken its spring tension.

Check Groove Fit: Ensure the groove is clean, correctly sized, and free of burrs to prevent improper seating or movement.

Inspect Circlips During Maintenance: Circlips should be replaced if they show signs of fatigue, corrosion, or distortion.

While they may be small in size, circlips are vital components in countless mechanical assemblies. The main distinction between internal circlips and external circlips lies in their installation location and how they secure components against axial movement. Both types are indispensable in applications ranging from simple consumer devices to complex hydraulic systems.

When choosing between them, it’s essential to consider where the retention is needed—inside a bore or around a shaft—as well as the operating environment, load, and maintenance requirements. In systems like hydraulic cylinders, the proper selection and installation of internal and external circlips help ensure long-term performance, safety, and structural integrity.