Using stainless steel for circlips offers several advantages that make it the material of choice in many industrial and mechanical applications. Here are the key benefits:

1. Corrosion Resistance

One of the biggest advantages of stainless steel is its excellent corrosion resistance. Unlike carbon steel or other metals, stainless steel contains chromium, which forms a protective oxide layer on the surface. This makes stainless steel circlips ideal for use in environments exposed to moisture, chemicals, and high humidity, such as in marine, food processing, or pharmaceutical industries.

2. Durability and Strength

Stainless steel is known for its high strength and toughness, making stainless steel circlips highly durable. These circlips can withstand heavy loads and mechanical stresses, ensuring they remain intact even under demanding conditions. This durability is especially important in machinery or applications where failure could lead to significant damage or downtime.

3. Resistance to High Temperatures

Stainless steel can maintain its strength and structural integrity at higher temperatures compared to many other materials. This makes stainless steel circlips suitable for use in high-temperature environments, such as automotive or industrial machinery, where other materials might weaken or deform under heat.

4. Formability and Flexibility

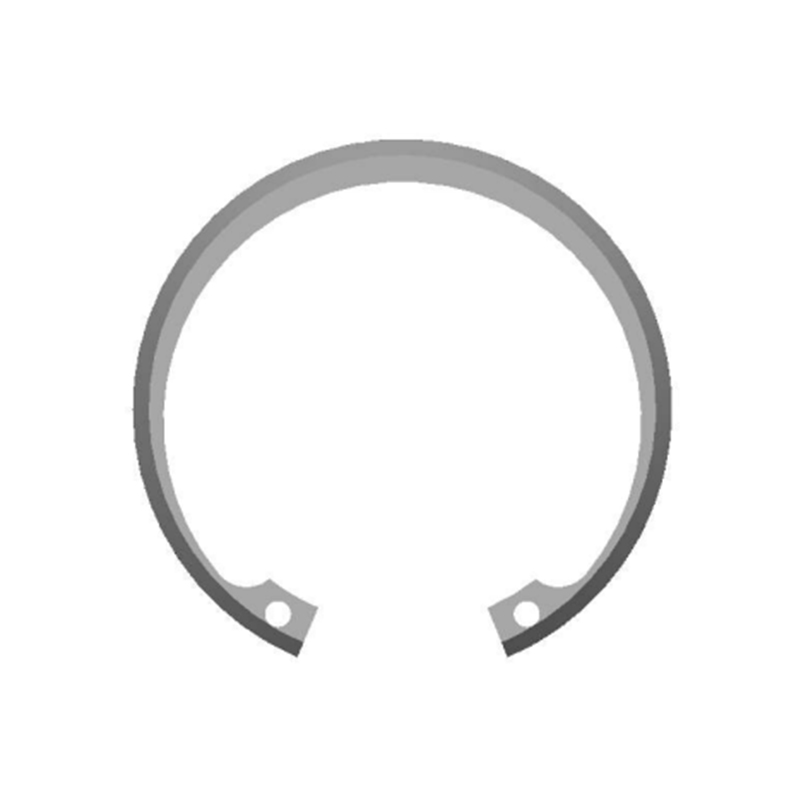

Stainless steel can be easily formed into precise shapes and sizes without compromising its strength. This makes it possible to manufacture stainless steel circlips in various designs, such as internal or external, to meet the specific requirements of different applications. Stainless steel circlips also have a certain amount of elasticity, which allows them to provide a strong, secure fit while still being flexible enough for installation and removal.

5. Resistance to Wear and Abrasion

Stainless steel is resistant to wear and abrasion, meaning that the circlips can endure long-term use without significant degradation. This makes them ideal for applications with moving parts, where the circlips are exposed to friction and mechanical forces.

6. Low Maintenance

Stainless steel circlips require minimal maintenance because of their resistance to corrosion, staining, and wear. Unlike other metals that may require frequent cleaning, coating, or replacement, stainless steel circlips often maintain their appearance and functionality over extended periods, reducing maintenance costs.

7. Versatility in Harsh Environments

Stainless steel is highly versatile and can perform well in both corrosive and extreme conditions. Whether it's exposure to chemicals, extreme temperatures, or marine environments, stainless steel circlips are capable of providing reliable performance in applications where other materials may fail.

8. Aesthetic Appeal

Stainless steel has a clean, shiny appearance, which can be desirable in applications where the appearance of components matters, such as in visible parts of machinery or decorative engineering applications.

9. Long Lifespan

Due to the combination of corrosion resistance, high strength, and durability, stainless steel circlips tend to have a long lifespan. This reduces the need for frequent replacements, improving the overall cost-effectiveness of using stainless steel in mechanical assemblies.

10. Non-Reactivity

Stainless steel is non-reactive with many substances, meaning it won’t react with oils, fuels, or chemicals commonly found in industrial applications. This feature ensures the integrity of the circlips, especially in sensitive or regulated industries like pharmaceuticals and food production.

11. Availability in Various Grades

Stainless steel comes in various grades (e.g., 304, 316, 410), allowing manufacturers to select the most appropriate grade based on the required properties for specific applications. This flexibility makes stainless steel circlips adaptable for a wide range of industries, from automotive to aerospace.

Stainless steel circlips offer significant advantages in terms of durability, resistance to corrosion, strength, and long-term performance. These qualities make them the material of choice for demanding environments and applications where reliability is crucial.