How DIN2093 Belleville Washers Prevent Loosening and Enhance Equipment Longevity

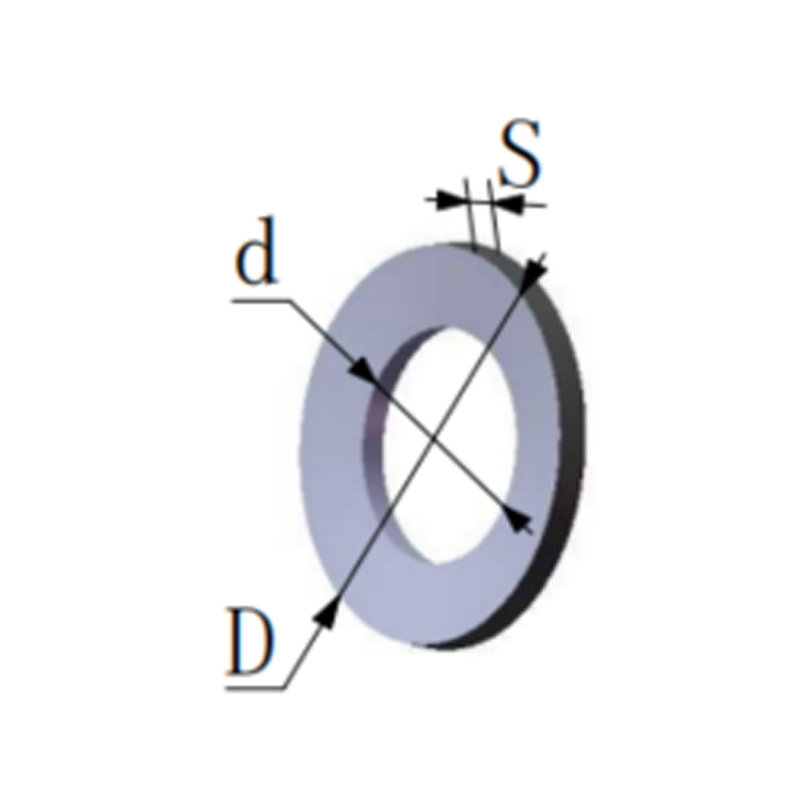

Belleville washers are conical-shaped springs designed to handle axial loads. When compressed under pressure, they store potential energy, which can be released when needed. This unique property makes them ideal for applications where consistent tension or compensation for bolt relaxation is required. The DIN2093 standard specifies the design, dimensions, and performance criteria for these washers, ensuring their quality and reliability across industries.

Made from high-performance materials such as 51CrV4, 50CrV4, 50CrVA, and 60Si2Mn , DIN2093 Belleville washers exhibit excellent fatigue resistance, corrosion resistance, and strength. Additionally, advanced surface treatments like phosphating, Dacromet, and Jumet further enhance their durability and adaptability to harsh environments.

How Do They Prevent Loosening?

One of the most significant challenges in mechanical assemblies is bolt loosening caused by vibration, thermal expansion, or dynamic loading. Over time, this can lead to leaks, misalignment, or even catastrophic failures. DIN2093 Belleville washers address this issue effectively through their ability to maintain constant pressure between flange connections.

When bolts begin to slacken due to external forces, the stored potential energy in the Belleville washer is released, compensating for any loss of preload. This self-adjusting mechanism ensures that the connection remains tight and secure, thereby preventing leaks and preserving the structural integrity of the assembly.

Moreover, the uniform stress distribution—from the inner diameter to the outer edge—ensures that the force applied is evenly distributed, minimizing localized stress concentrations that could otherwise lead to premature failure.

Enhancing Equipment Longevity

Beyond preventing loosening, DIN2093 Belleville washers contribute significantly to extending the lifespan of equipment. Here’s how:

Shock Absorption : These washers act as dampers, absorbing shocks and vibrations that would otherwise transfer directly to fasteners and surrounding components. By cushioning these impacts, they reduce wear and tear on critical parts, prolonging their operational life.

Protection of Fasteners : The controlled deformation of Belleville washers helps shield bolts and nuts from excessive strain, reducing the risk of thread stripping, galling, or breakage. This protection is especially important in high-stress environments such as automotive, aerospace, and industrial machinery.

Adaptability to Dynamic Conditions : Whether it's temperature fluctuations, varying loads, or cyclic stresses, DIN2093 Belleville Spring Washer provide consistent performance under changing conditions. Their ability to adapt ensures stable operation and minimizes maintenance needs over time.

Customization for Specific Applications : Companies like Anhui Ningguo Dongbo Fastener offer tailored solutions to meet specific requirements. From material selection to custom dimensions and surface treatments, these washers can be optimized for virtually any application, further enhancing their effectiveness.

Applications Across Industries

The versatility of DIN2093 Belleville washers makes them indispensable in a wide range of sectors:

Automotive : Used in suspension systems, engine mounts, and braking mechanisms to absorb shocks and prevent loosening.

Energy : Critical in pipelines, valves, and turbines to maintain sealing pressures and resist vibrational forces.

Construction : Employed in heavy machinery and structural joints to ensure stability and safety.

Electronics : Provide precise tension control in delicate assemblies, protecting sensitive components from damage.