Axial Fixation Made Easy: Benefits of Using M1800 Crescent E-Clips in Mechanical Design

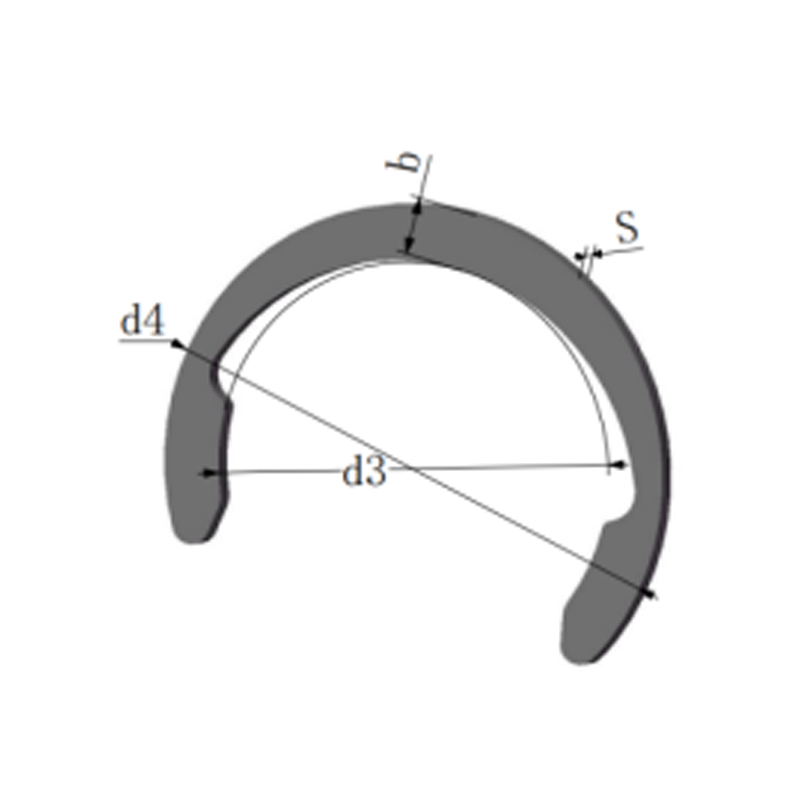

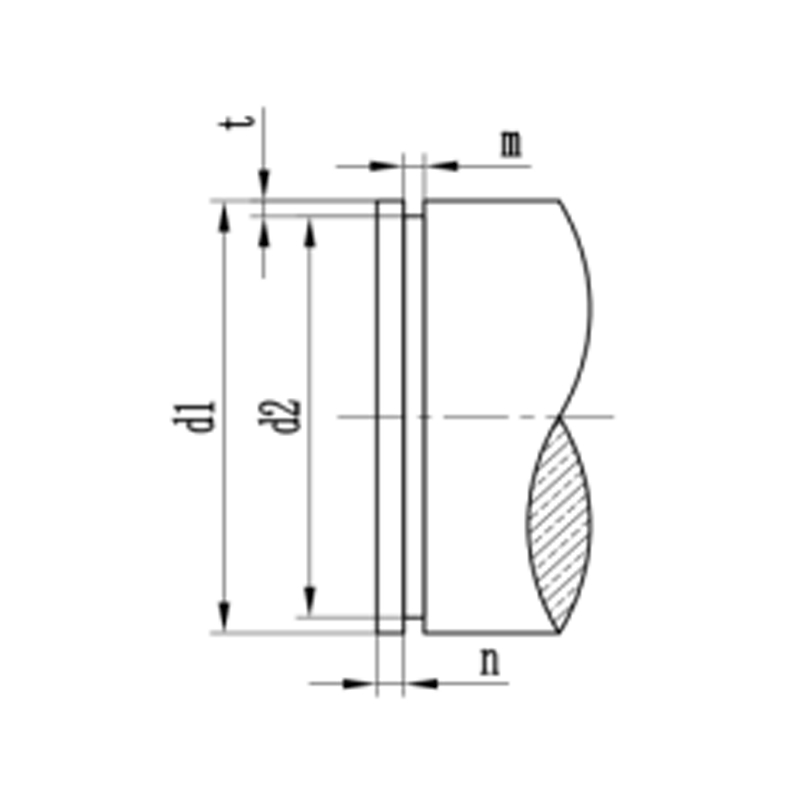

Crescent E-Clips, also known as crescent-shaped open-end retaining rings or clamping retaining rings, are named for their distinctive crescent moon-like shape. These clips are designed to fit snugly around a shaft, providing robust axial retention for components like bearings, gears, pulleys, and sprockets. The M1800 model, in particular, is engineered to deliver exceptional performance under demanding conditions, making it an ideal choice for a wide range of mechanical applications.

Key Benefits of Using M1800 Crescent E-Clips

1. Effortless Installation and Removal

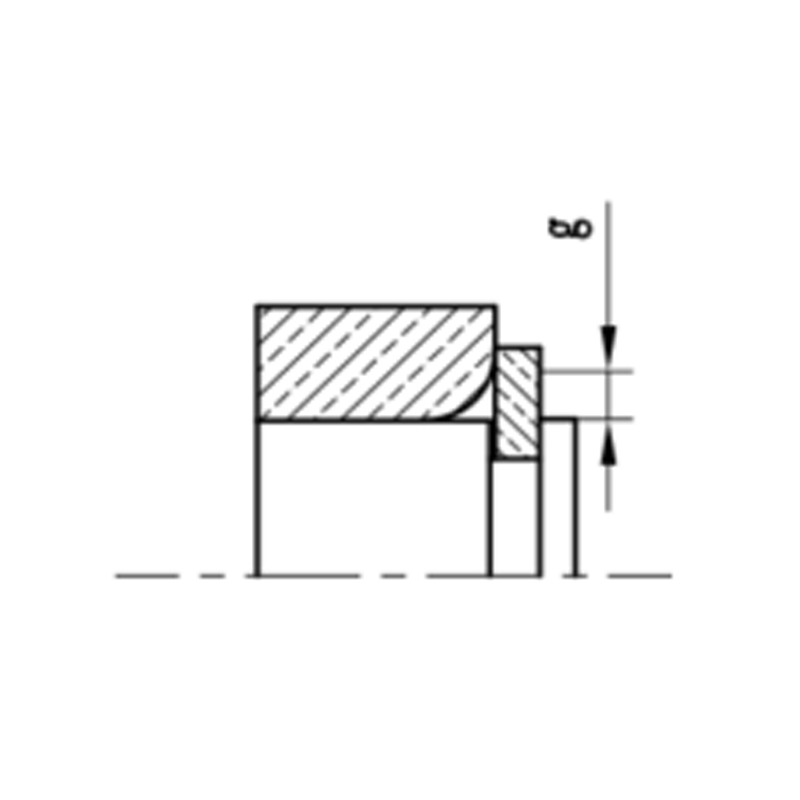

One of the standout features of the M1800 Crescent E-Clip is its ease of installation. Unlike traditional retaining methods that may require complex tools or processes, these clips can be installed quickly using simple hand tools. Their open-ended design allows them to slide easily onto the shaft, while their spring-like tension ensures a secure grip once in place. Additionally, they can be removed just as effortlessly when maintenance or replacement is needed, saving time and labor costs.

2. Superior Axial Retention

The primary function of any retaining ring is to prevent axial movement, and the M1800 Crescent E-Clip excels in this regard. Its unique crescent shape provides uniform pressure distribution along the shaft, effectively locking components in position and preventing unwanted displacement. Whether your application involves high-speed rotation or heavy loads, the M1800 ensures stability and reliability.

3. Versatile Material Options

To meet diverse operational requirements, the M1800 Crescent E-Clip for Shaft Applications is available in both conventional carbon steel and stainless steel variants. Common materials include 65Mn , C67S , 2Cr13 , 304 , and 1.4122 , each offering specific advantages depending on the environment. For example:

Carbon Steel : Ideal for general-purpose applications requiring strength and durability.

Stainless Steel : Perfect for corrosive environments or applications involving exposure to moisture or chemicals.

This versatility makes the M1800 suitable for industries ranging from automotive and aerospace to marine and agriculture.

4. Enhanced Durability Through Surface Treatments

Surface treatment plays a crucial role in extending the lifespan of fasteners. Anhui Ningguo Dongbo Fastener offers a variety of standard surface treatments for the M1800 Crescent E-Clip, including:

Phosphating : Provides corrosion resistance and improves lubricity.

Dacromet and Jumet Coatings : Offer superior protection against rust and wear.

Zinc Plating and Zinc-Nickel Plating : Enhance resistance to environmental factors.

Electrophoresis : Delivers excellent adhesion and aesthetic appeal.

These advanced treatments ensure that the M1800 performs consistently even in harsh operating conditions.

5. Cost-Effective Solution

Compared to alternative methods of axial fixation, such as threaded fasteners or custom machining, the M1800 Crescent E-Clip offers significant cost savings. Its standardized design eliminates the need for expensive modifications, while its reusability reduces long-term maintenance expenses. For businesses looking to optimize their budgets without compromising quality, the M1800 is an intelligent choice.

Applications Across Industries

The adaptability of the M1800 Crescent E-Clip makes it indispensable across multiple sectors:

Automotive : Securing components in engines, transmissions, and drivetrains.

Industrial Machinery : Supporting gears, pulleys, and conveyor systems.

Aerospace : Ensuring precision and reliability in flight-critical assemblies.

Renewable Energy : Facilitating efficient operation in wind turbines and solar trackers.

Marine : Withstanding saltwater exposure and vibration in shipboard equipment.

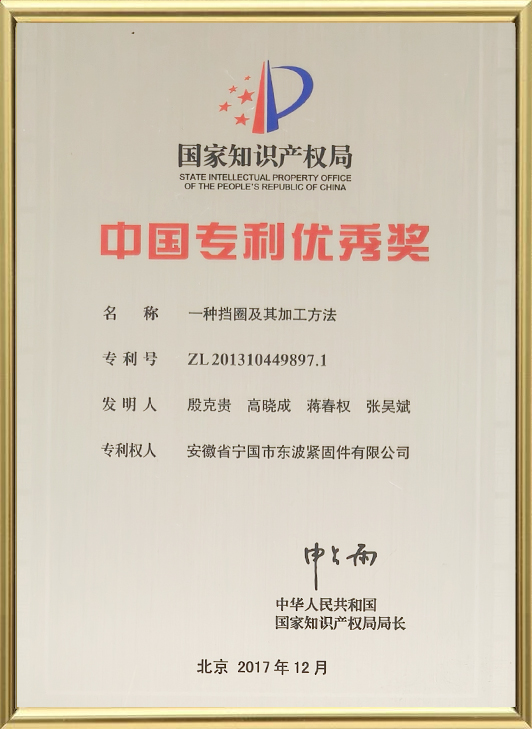

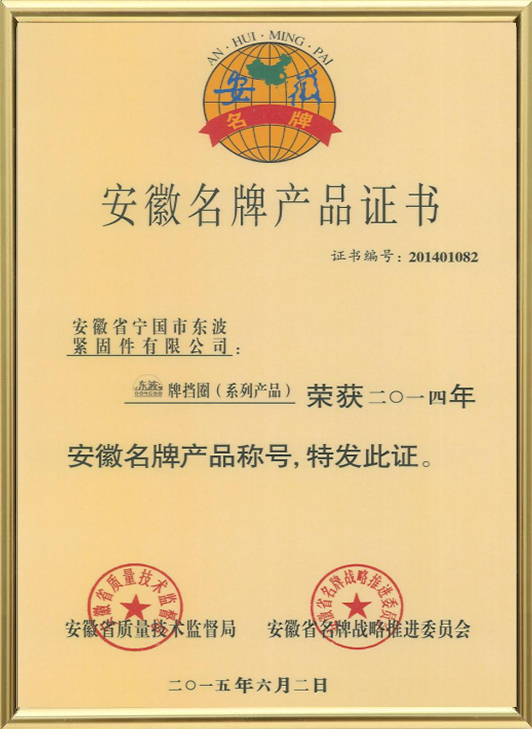

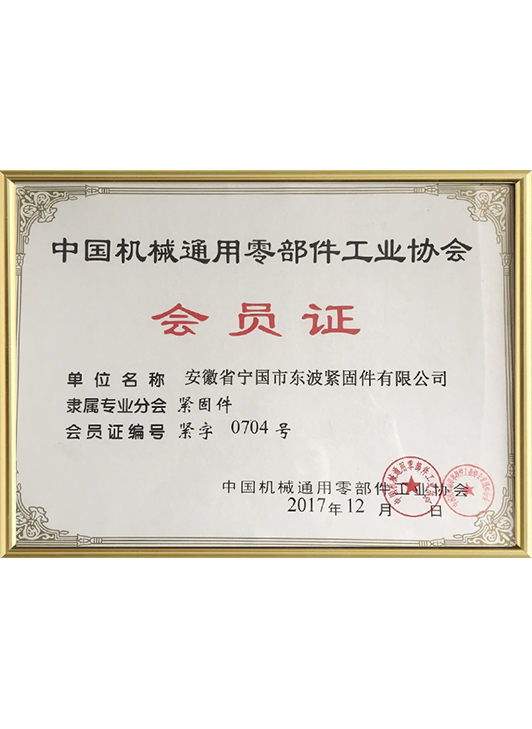

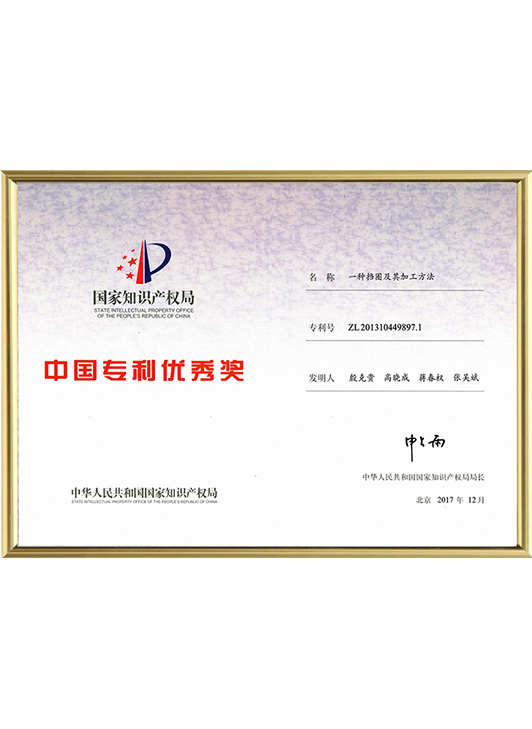

Since its establishment in September 2005, Anhui Ningguo Dongbo Fastener Co., Ltd. has been synonymous with innovation, quality, and customer satisfaction. With over four decades of experience in producing retaining rings, washers, elastic cylindrical pins, and other precision fasteners, the company has earned a reputation as a global leader in the industry. Located in the prestigious Ningguo Economic and Technological Development Zone, Dongbo boasts state-of-the-art manufacturing facilities, a skilled workforce of more than 530 employees, and a commitment to continuous improvement.

Dongbo’s dedication to excellence extends beyond mass production to include comprehensive customization services. From standard products to tailored solutions, the company leverages its strong technical capabilities to address even the most challenging application needs. As a testament to its expertise, Dongbo holds numerous patents and certifications, solidifying its status as a high-tech enterprise.