The Role of 15-Degree Beveling in N1402 Retaining Rings for Enhanced Shaft Fixation

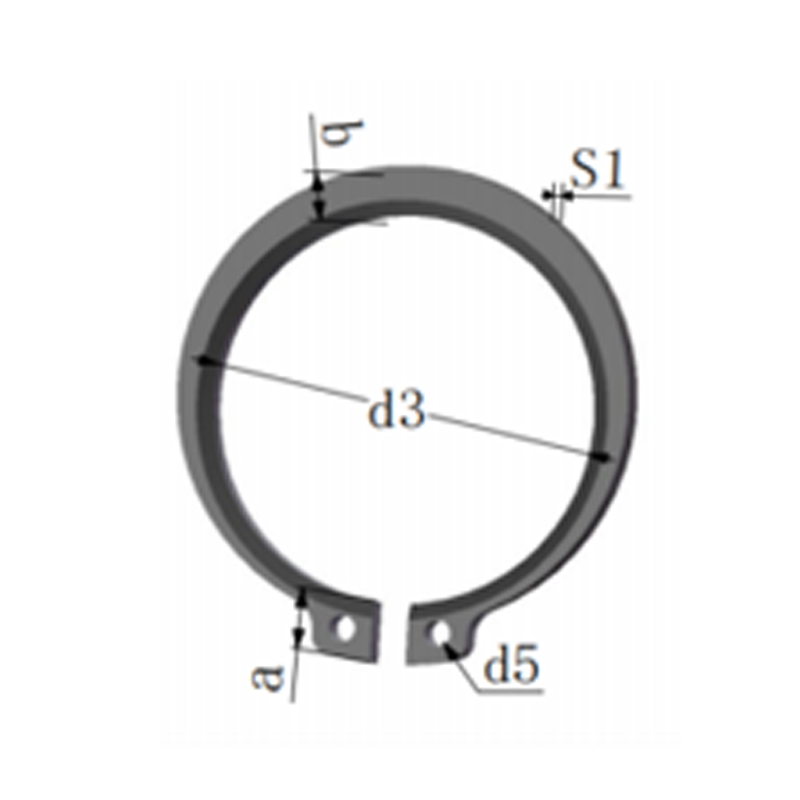

A retaining ring is a circular fastener that fits into a groove on a shaft or inside a housing bore. Its primary function is to hold other components in place, restricting their axial movement along the shaft. These rings are widely used across industries such as automotive, aerospace, construction, and manufacturing due to their reliability, ease of installation, and cost-effectiveness.

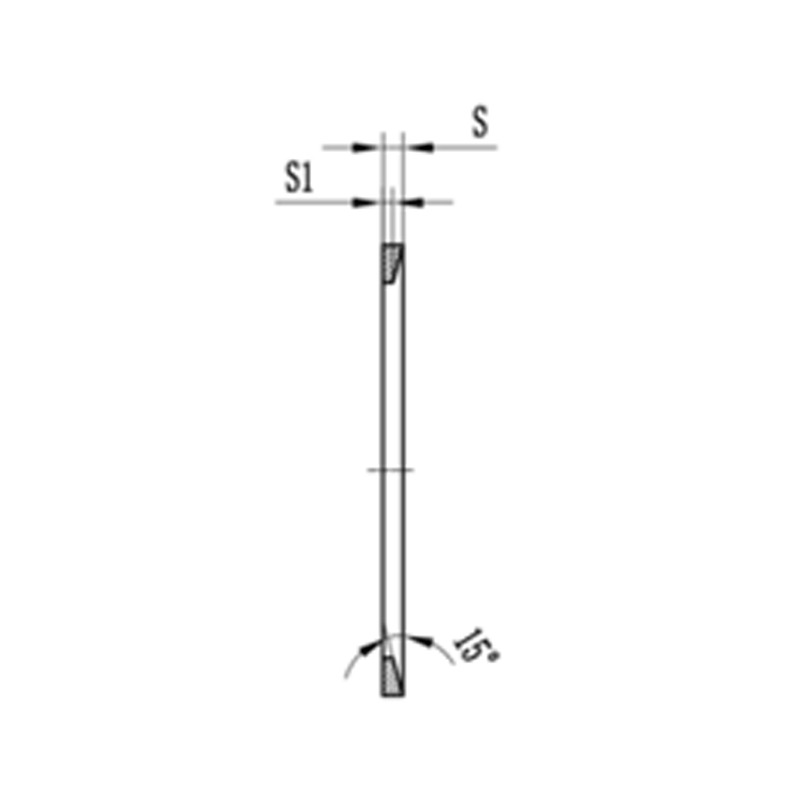

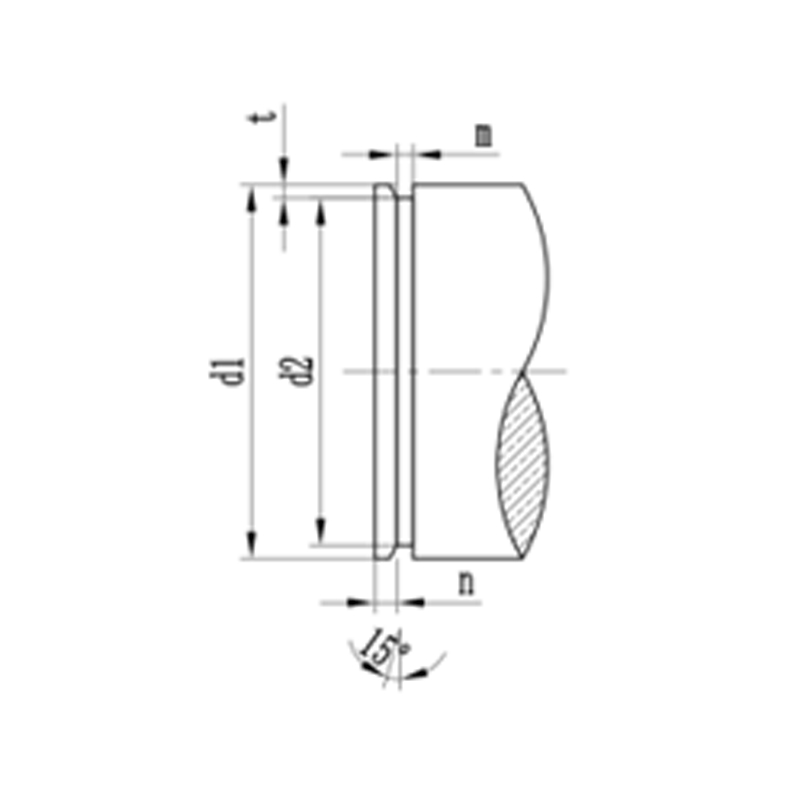

The N1402 External 15-Degree Beveled Retaining Ring takes this functionality a step further with its unique design, which includes a precisely engineered 15-degree bevel on its inner diameter. This subtle yet significant modification enhances the performance of the retaining ring, making it an ideal choice for applications requiring superior stability and durability.

Why Does the 15-Degree Bevel Matter?

The 15-degree beveling on the N1402 retaining ring serves multiple purposes, each contributing to improved performance:

1. Improved Installation Precision

Installing a retaining ring requires careful alignment with the corresponding groove on the shaft. The 15-degree bevel acts as a guide during installation, allowing the ring to seat more easily and accurately into the groove. This reduces the risk of misalignment, which could compromise the integrity of the assembly.

2. Enhanced Grip and Stability

The beveled edge creates a tighter fit between the retaining ring and the groove, minimizing any potential play or slippage. This ensures that the secured components remain firmly in position, even under high-stress conditions or dynamic loads.

3. Prevention of Component Damage

Without proper beveling, sharp edges on the retaining ring can cause wear or damage to both the shaft and adjacent components over time. The 15-degree chamfer distributes stress more evenly, reducing friction and protecting the surface of the shaft from abrasion.

4. Compatibility with Groove Design

For optimal performance, the retaining ring must match the geometry of the groove it is installed in. The N1402’s 15-degree bevel corresponds perfectly with grooves designed with the same angle, ensuring seamless integration and maximum effectiveness.

Applications of the N1402 Retaining Ring

The versatility of the N1402 External 15-Degree Beveled Retaining Ring makes it suitable for a wide range of applications, including but not limited to:

Automotive Industry: Securing gears, pulleys, and bearings in transmissions and engines.

Industrial Machinery: Holding components in place in conveyor systems, pumps, and compressors.

Aerospace Engineering: Ensuring reliable fixation in lightweight yet robust assemblies.

Construction Equipment: Supporting heavy-duty operations in cranes, excavators, and drilling rigs.

Its ability to provide consistent and dependable fixation in demanding environments underscores why the N1402 retaining ring is trusted by engineers worldwide.

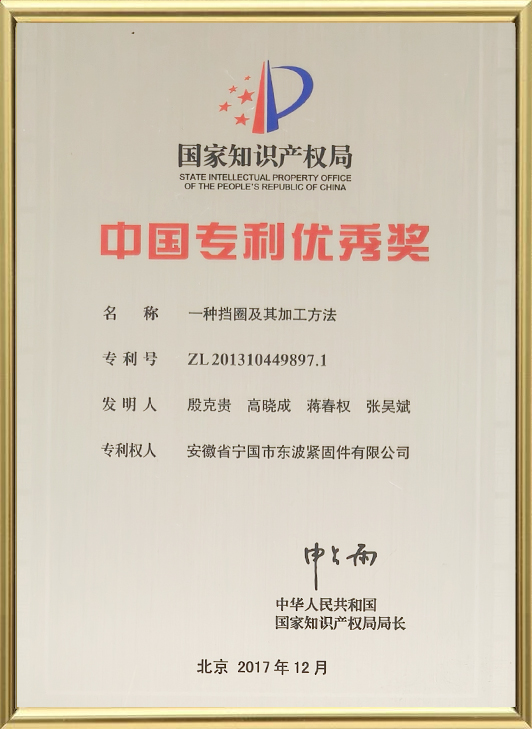

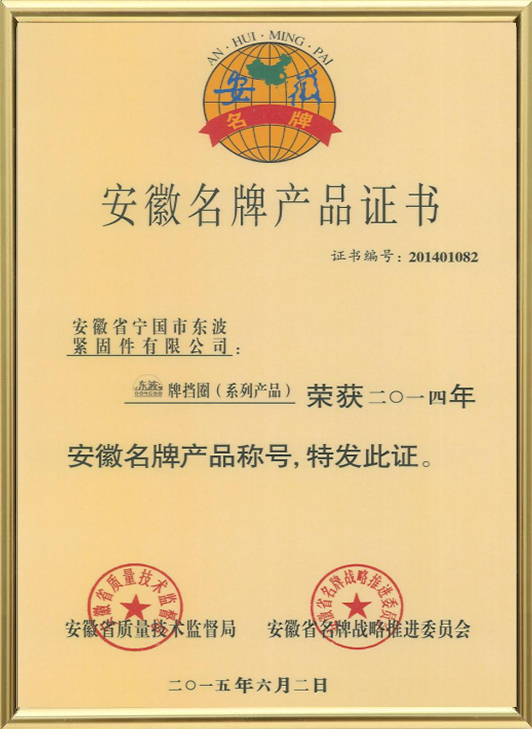

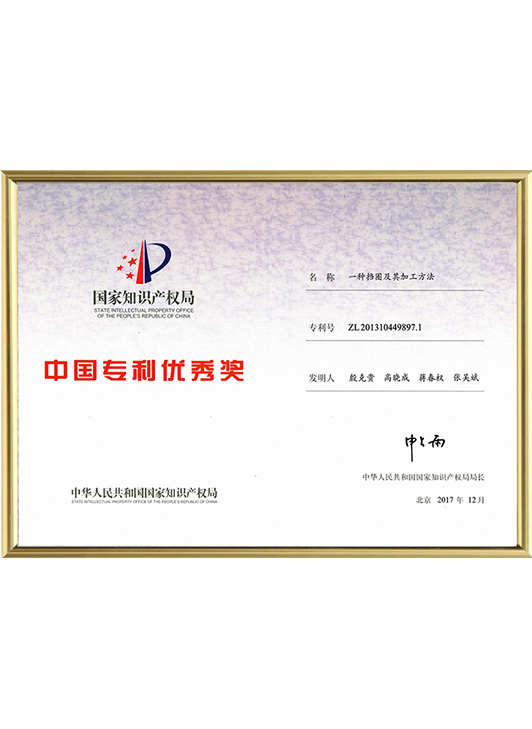

A Commitment to Innovation and Quality

At the heart of Dongbo Fastener’s success lies a steadfast commitment to quality and innovation. From mass-produced standard parts to fully customized one-stop solutions, the company leverages its strong technical development capabilities to address complex application challenges. By adhering to rigorous quality control processes and maintaining ISO certifications, they ensure that every product leaving their facility meets the highest standards of performance and reliability.

The N1402 External 15-Degree Beveled Retaining Ring exemplifies this philosophy. Designed with meticulous attention to detail, it embodies the perfect balance of form and function—providing users with a solution that is both practical and efficient.