Advanced Surface Treatments for DIN983 External Circlips: Phosphating, Zinc Plating, and More from Dongbo

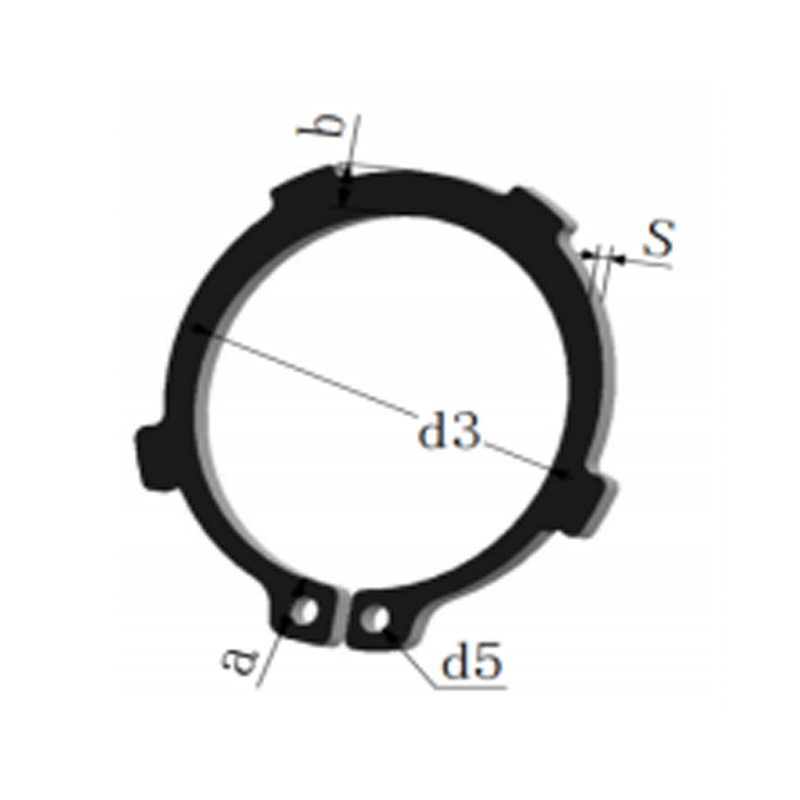

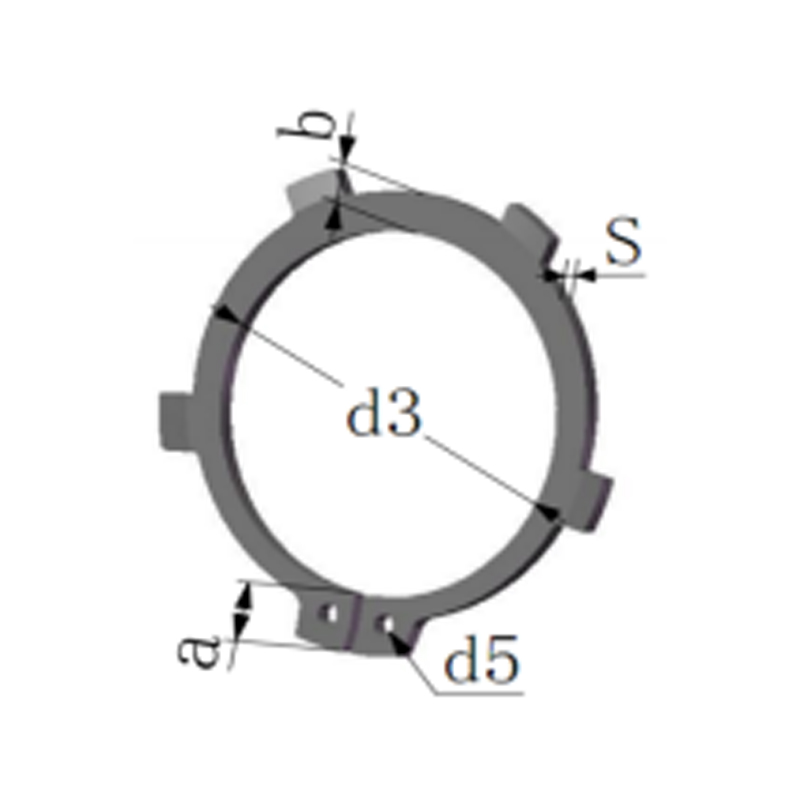

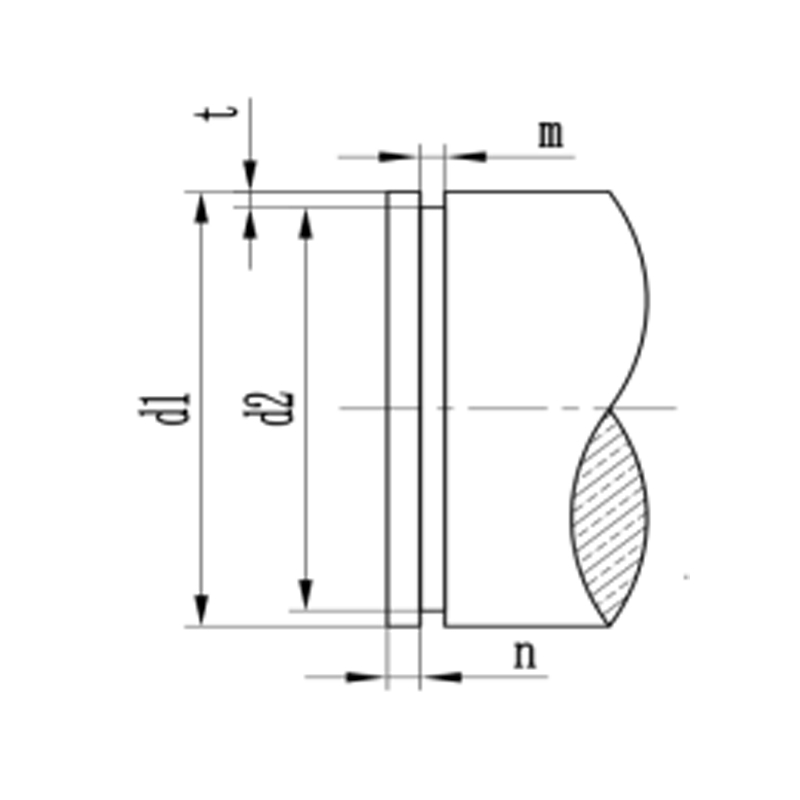

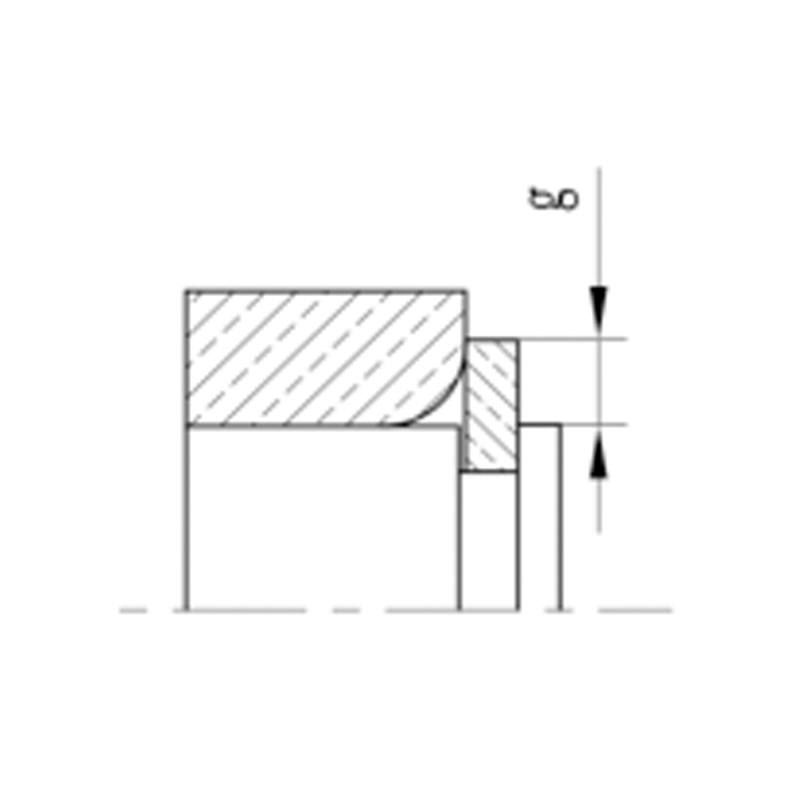

External circlips with lugs are critical components in machinery, designed to prevent axial movement and ensure stability under demanding conditions. However, exposure to harsh environments, moisture, or mechanical stress can compromise their longevity and functionality. This is where advanced surface treatments come into play—providing an additional layer of protection while maintaining the structural integrity of the circlips.

At Dongbo, we offer a wide range of surface treatment options tailored to meet diverse application needs:

1. Phosphating

Benefits : Phosphating creates a protective phosphate coating that enhances corrosion resistance and improves adhesion for subsequent coatings like paints or oils. It is ideal for applications requiring moderate environmental protection.

Applications : Suitable for general industrial use, especially in environments where lubrication retention is essential.

2. Zinc Plating

Benefits : Zinc plating provides excellent corrosion resistance by forming a sacrificial barrier that protects the base metal. It is cost-effective and widely used across various industries.

Applications : Perfect for outdoor and indoor applications exposed to moisture or mild corrosive conditions.

3. Zinc-Nickel Plating

Benefits : Offering superior corrosion resistance compared to standard zinc plating, zinc-nickel plating is highly durable and performs exceptionally well in extreme environments.

Applications : Ideal for automotive, marine, and heavy machinery industries where high-performance coatings are required.

4. Dacromet Coating

Benefits : Dacromet is a high-performance, chrome-based coating known for its exceptional resistance to corrosion, heat, and chemicals. It also provides a smooth finish without adding significant thickness.

Applications : Best suited for applications involving high temperatures, salt spray exposure, or chemical contact.

5. Electrophoretic Coating (Electrophoresis)

Benefits : This electrochemical process deposits a uniform, thin film over the component, providing excellent corrosion resistance and aesthetic appeal.

Applications : Commonly used in industries requiring precise finishes, such as electronics and precision instruments.

6. Jumet Coating

Benefits : Jumet is a specialized coating that combines anti-corrosion properties with enhanced wear resistance, making it suitable for challenging environments.

Applications : Widely adopted in construction equipment, agricultural machinery, and other heavy-duty applications.

Material Excellence Combined with Surface Innovation

Our DIN983 external circlips with lugs are crafted from premium materials, including conventional carbon steel (65Mn, C67S) and stainless steel (2Cr13, 304, 1.4122) . These materials are carefully selected for their strength, flexibility, and ability to withstand impacts during operation. When paired with advanced surface treatments, these circlips deliver unmatched performance in even the most demanding applications.

Carbon Steel Options : Known for their toughness and affordability, carbon steel circlips benefit significantly from treatments like zinc plating and phosphating to enhance durability.

Stainless Steel Options : Already resistant to rust and corrosion, stainless steel circlips gain additional protection through electrophoretic coating or Dacromet, extending their lifespan further.

A Legacy of Quality and Customization

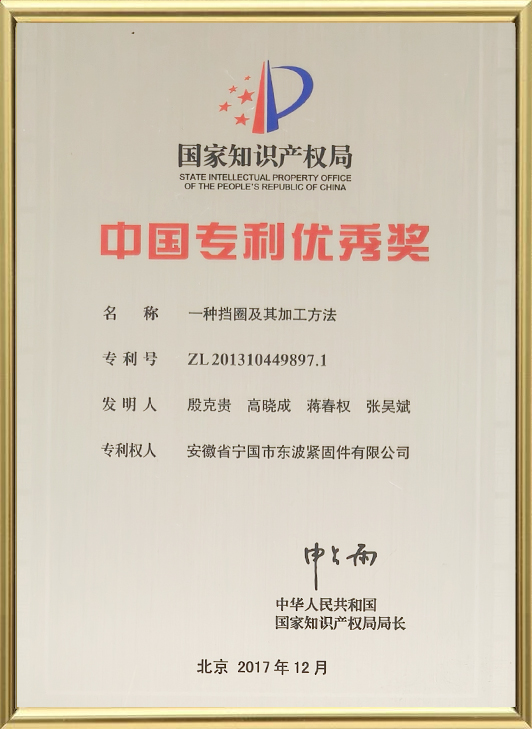

Established in September 2005, Anhui Ningguo Dongbo Fastener Co., Ltd. has grown into a globally recognized leader in the fastener industry. Located in the prestigious Ningguo Economic and Technological Development Zone , our state-of-the-art facility spans 91 acres and employs over 530 skilled professionals. With 46 years of expertise in producing retaining rings, washers, elastic cylindrical pins, and other precision-engineered components, we have earned a reputation for delivering both standardized products and customized solutions .

At Dongbo, we believe that innovation begins with understanding customer needs. Whether you require off-the-shelf DIN983 external circlips or bespoke designs with unique specifications, our team collaborates closely with you to develop solutions that align perfectly with your operational requirements.