DIN6799 Resilient Spring Steel External E-Clip: The Backbone of Axial Positioning in Bearings

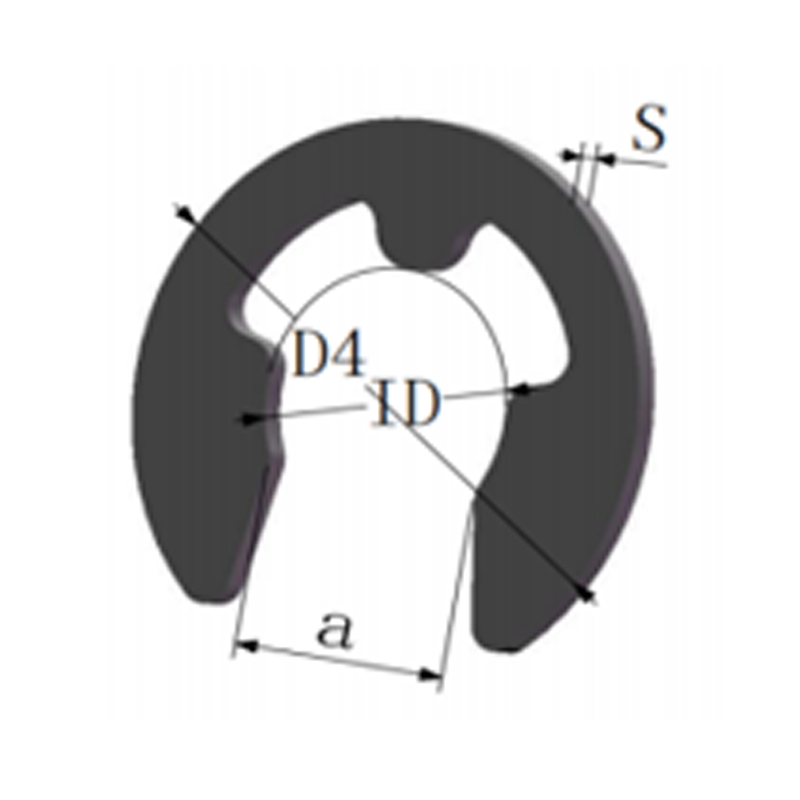

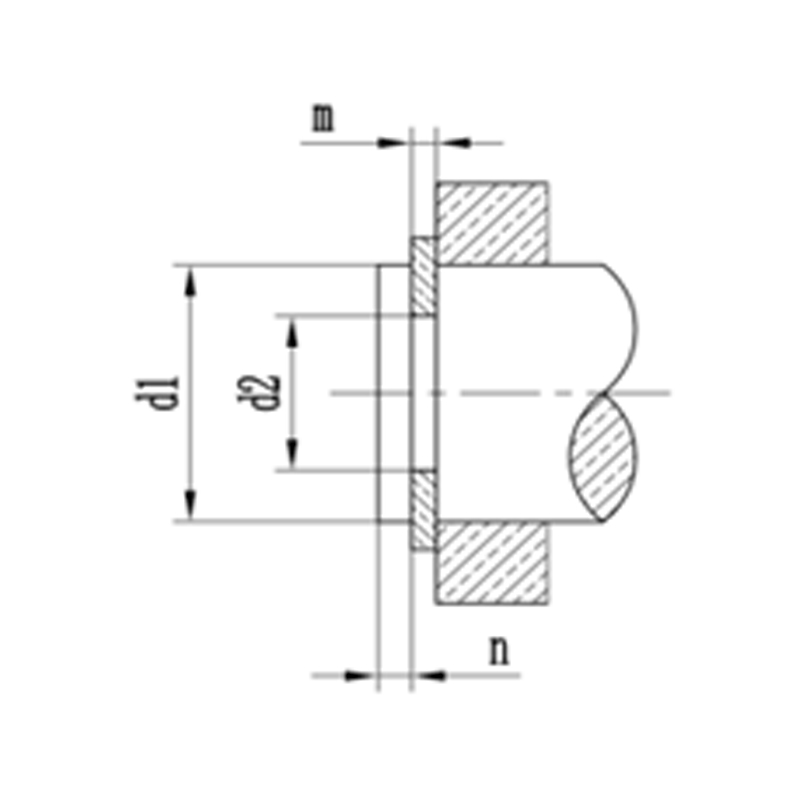

The DIN6799 Resilient Spring Steel External E-Clip is an open retaining ring shaped like the letter "E." Its primary function is to hold bearings, gears, and other components securely on shafts, preventing unwanted axial movement. This simple yet ingenious design ensures that critical parts remain in their designated positions, even under high-stress conditions.

What sets the DIN6799 apart is its resilience and adaptability. Made from high-quality materials such as carbon steel or stainless steel, it combines strength with flexibility, making it suitable for a wide range of applications. Whether used in agricultural machinery, automotive systems, or industrial equipment, the DIN6799 E-Clip delivers consistent performance.

Why the DIN6799 E-Clip Is Essential for Axial Positioning

1. Precision in Axial Fixation

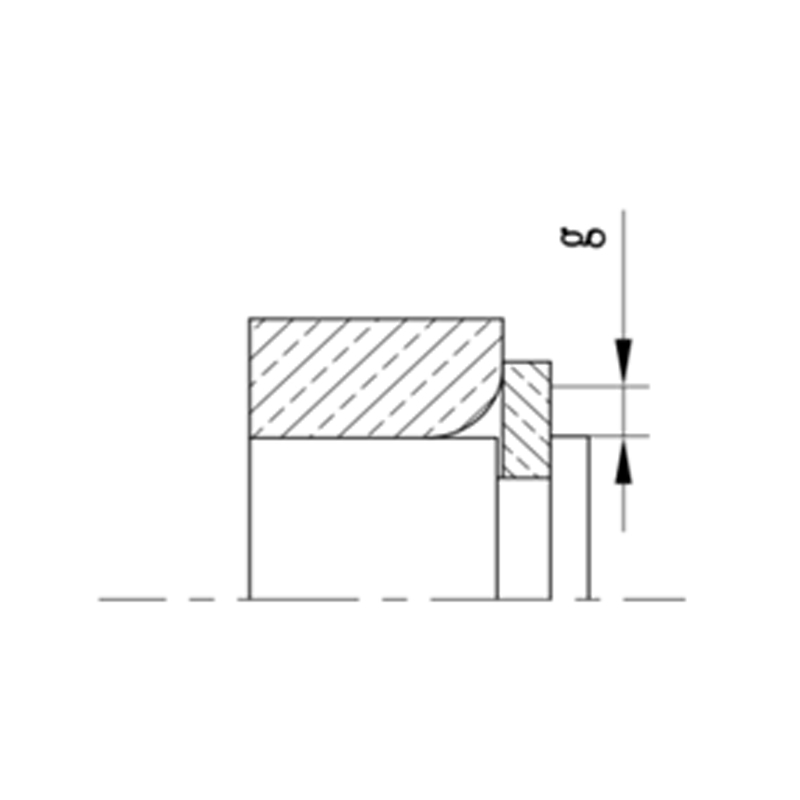

Bearings and gears must be precisely positioned along a shaft to ensure proper alignment and functionality. The DIN6799 E-Clip provides a reliable method for limiting axial movement, ensuring that components stay securely in place without compromising rotational freedom.

2. Resilience Under Pressure

The spring steel construction of the DIN6799 allows it to maintain its shape and tension over time, even when subjected to repeated stress or vibration. This resilience makes it ideal for demanding environments where failure is not an option.

3. Wide Range of Applications

From agricultural equipment to automotive transmissions, the DIN6799 E-Clip is used wherever rotating components require secure axial positioning. Its versatility and compatibility with various shaft sizes make it a go-to choice for engineers and designers.

4. Ease of Installation

Designed for simplicity, the DIN6799 E-Clip can be quickly installed using standard tools. Its open design allows for easy removal and replacement, reducing downtime during maintenance or repairs.

Material Options and Surface Treatments

To meet diverse application requirements, the DIN6799 Resilient Spring Steel External E-Clip is available in a variety of materials and surface treatments:

Materials:

Carbon Steel (e.g., 65Mn, C67S): Offers excellent tensile strength and durability, making it ideal for heavy-duty applications.

Stainless Steel (e.g., 2Cr13, 304, 1.4122): Provides superior corrosion resistance, making it suitable for harsh environments or food-grade applications.

Surface Treatments:

Phosphating: Enhances wear resistance and reduces friction.

Dacromet and Jumet Coatings: Provide exceptional corrosion protection and thermal stability.

Zinc Plating and Zinc-Nickel Plating: Offer enhanced rust resistance and aesthetic appeal.

Electrophoresis: Delivers a uniform coating with excellent adhesion and durability.

These material and treatment options ensure that the DIN6799 E-Clip can be tailored to meet specific operational demands, whether it’s resisting corrosion in marine environments or enduring high temperatures in industrial settings.

Applications Across Industries

The DIN6799 Resilient Spring Steel External E-Clip finds applications in virtually every industry that relies on rotating machinery:

Automotive Industry: Secures bearings and gears in engines, transmissions, and drivetrains.

Agricultural Machinery: Ensures stable operation of components in tractors, harvesters, and irrigation systems.

Industrial Equipment: Supports the functioning of conveyor systems, pumps, compressors, and turbines.

Construction Machinery: Provides reliable fixation in cranes, excavators, and drilling rigs.

Its ability to perform consistently in diverse environments underscores its importance as a foundational component in modern engineering.

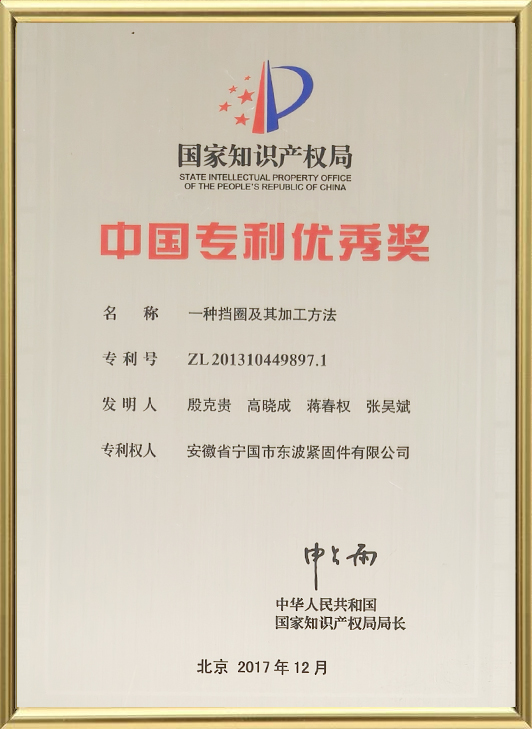

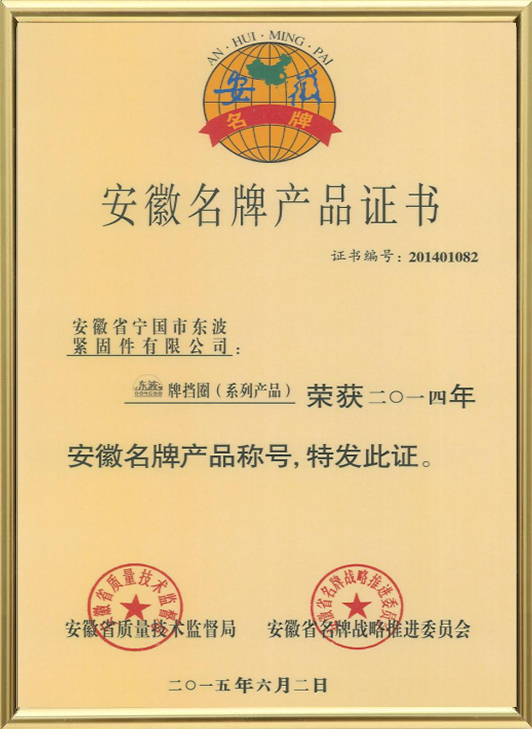

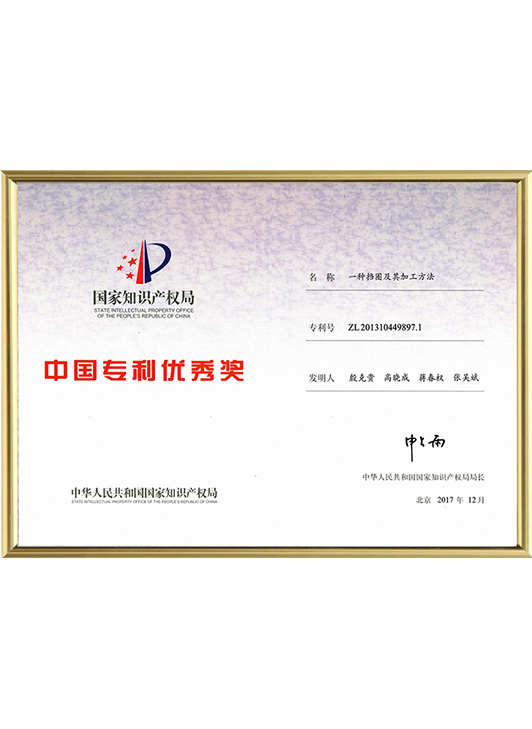

Innovation and Customization at the Core

At the heart of Dongbo Fastener’s success lies a commitment to innovation and customer satisfaction. From mass-produced standard parts to fully customized one-stop solutions, the company leverages its strong technical development capabilities to address complex application challenges. By adhering to rigorous quality control processes and maintaining ISO certifications, they ensure that every product leaving their facility meets the highest standards of performance and reliability.

The DIN6799 Resilient Spring Steel External E-Clip exemplifies this philosophy. Designed with meticulous attention to detail, it embodies the perfect balance of form and function—providing users with a solution that is both practical and efficient.