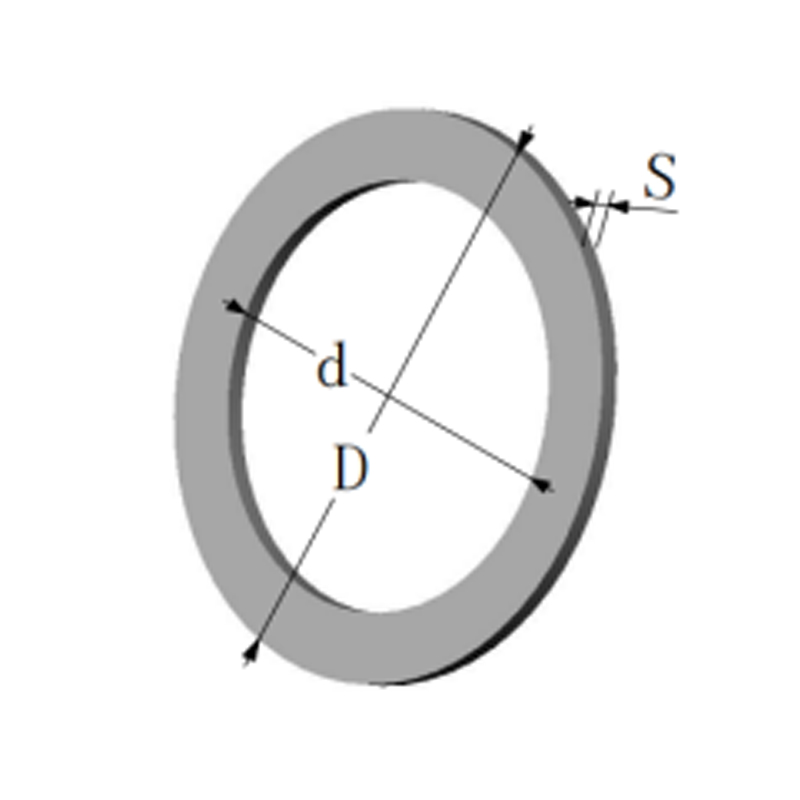

Hardened vs. Non-Hardened DIN988 Washers: Understanding Their Unique Uses

Hardened DIN988 washers undergo a heat treatment process that increases their hardness and strength. This makes them highly resistant to deformation under high loads and stress. Typically made from materials such as 65Mn, C67S, or stainless steel grades like 301 , hardened washers are ideal for applications where maintaining structural integrity is paramount.

Key Characteristics:

High tensile strength : Resists bending or breaking under heavy loads.

Durability : Withstands wear and tear in demanding environments.

Precision : Maintains shape and function even under extreme conditions.

Common Applications:

Heavy machinery : Used in construction equipment, industrial presses, and hydraulic systems where high load-bearing capacity is required.

Automotive industry : Employed in suspension systems, engine mounts, and other high-stress areas.

Structural engineering : Ensures stability in bridges, buildings, and other infrastructure projects.

What Are Non-Hardened DIN988 Washers?

Non-hardened DIN988 washers, on the other hand, are not subjected to heat treatment and retain a softer, more malleable structure. Made from materials such as conventional carbon steel (DC01, SPCC) or stainless steel grades like 304 , these washers are better suited for applications where flexibility, corrosion resistance, or cost-effectiveness is prioritized over extreme hardness.

Key Characteristics:

Flexibility : Can conform slightly to uneven surfaces, providing better sealing or isolation.

Corrosion resistance : Often used in environments exposed to moisture or chemicals when made from stainless steel.

Cost-effective : Generally less expensive than hardened washers, making them suitable for low-load applications.

Common Applications:

General-purpose fastening : Ideal for light-duty tasks in household appliances, furniture assembly, and electronics.

Corrosive environments : Stainless steel non-hardened washers are widely used in marine, food processing, and medical equipment.

Adjusting spacers : Frequently employed in automotive parts as precision spacers due to their ability to be ground to exact thicknesses.

Choosing Between Hardened and Non-Hardened Washers

Selecting the appropriate type of DIN988 Flat Washers depends on several factors, including the application's requirements, environmental conditions, and budget constraints. Here’s a breakdown to help you decide:

Load-Bearing Capacity : If your application involves heavy loads or high stress, opt for hardened washers to ensure they won’t deform or fail.

Environmental Factors : For corrosive or wet environments, choose non-hardened stainless steel washers for their superior resistance to rust and chemical damage.

Surface Protection : Both types can protect surfaces, but if the surface is delicate or prone to scratching, non-hardened washers may offer gentler contact.

Cost Considerations : For non-critical applications where maximum strength isn’t necessary, non-hardened washers provide an economical solution without compromising functionality.

Surface Treatments for Enhanced Performance

Regardless of whether you choose hardened or non-hardened DIN988 washers, surface treatments can significantly enhance their performance and longevity. Common options include:

Phosphating : Provides mild corrosion resistance and improves lubricity.

Zinc plating : Offers excellent protection against rust in outdoor or humid environments.

Dacromet and Jumet coatings : Deliver superior corrosion resistance and are often used in automotive and industrial applications.

Electrophoresis : Creates a durable, uniform coating that resists chipping and peeling.

At Anhui Ningguo Dongbo Fastener Co., Ltd. , we specialize in offering a wide range of DIN988 washers with various materials and surface treatments to meet diverse customer needs. Our expertise ensures that every washer we produce adheres to the highest quality standards, delivering reliable performance across industries.

With decades of experience in manufacturing retaining rings, washers, and other fastening solutions, Anhui Ningguo Dongbo Fastener Co., Ltd. has earned a reputation for excellence. Located in the Ningguo Economic and Technological Development Zone , our state-of-the-art facilities and skilled team enable us to deliver both standard and customized DIN988 washers tailored to your specifications.

Whether you need hardened washers for heavy-duty applications or non-hardened washers for general use, we have the expertise and resources to meet your requirements. Our commitment to innovation, quality, and customer satisfaction ensures that you receive products that exceed expectations.