The Role of DIN 472 Circlips in Ensuring Secure Axial Positioning in Circular Holes

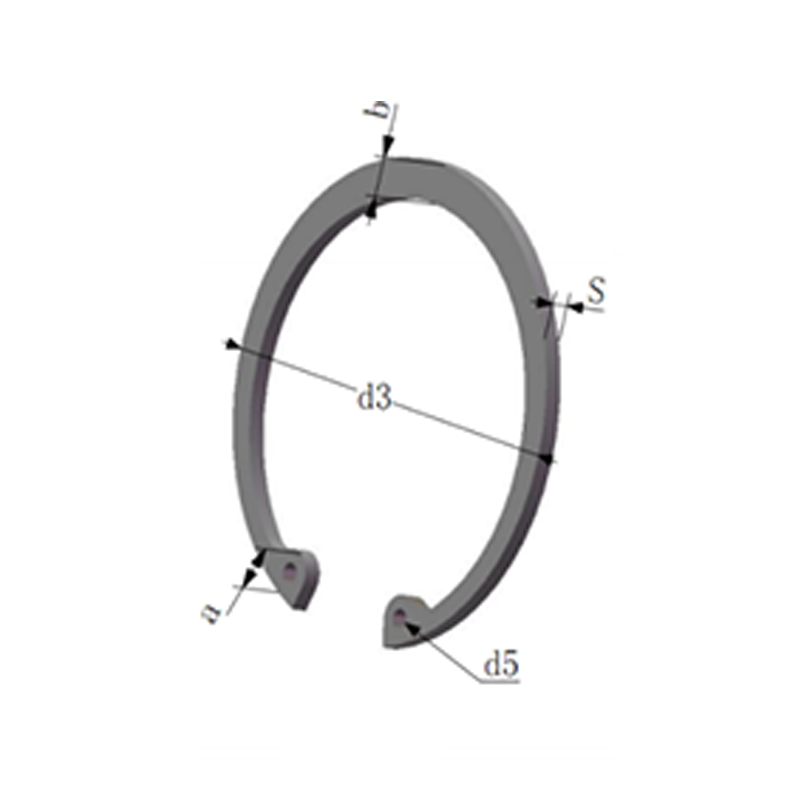

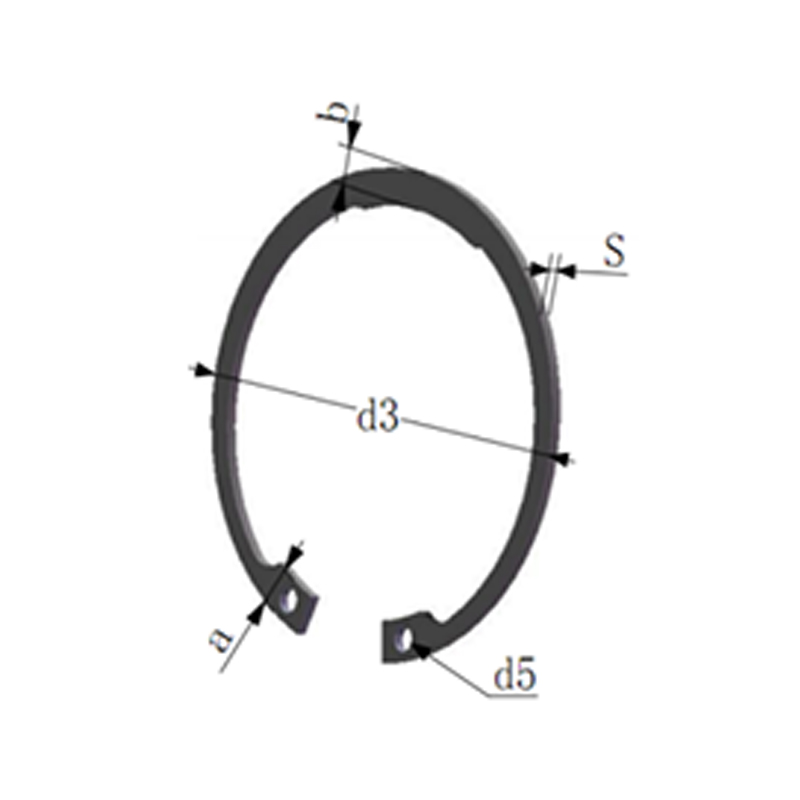

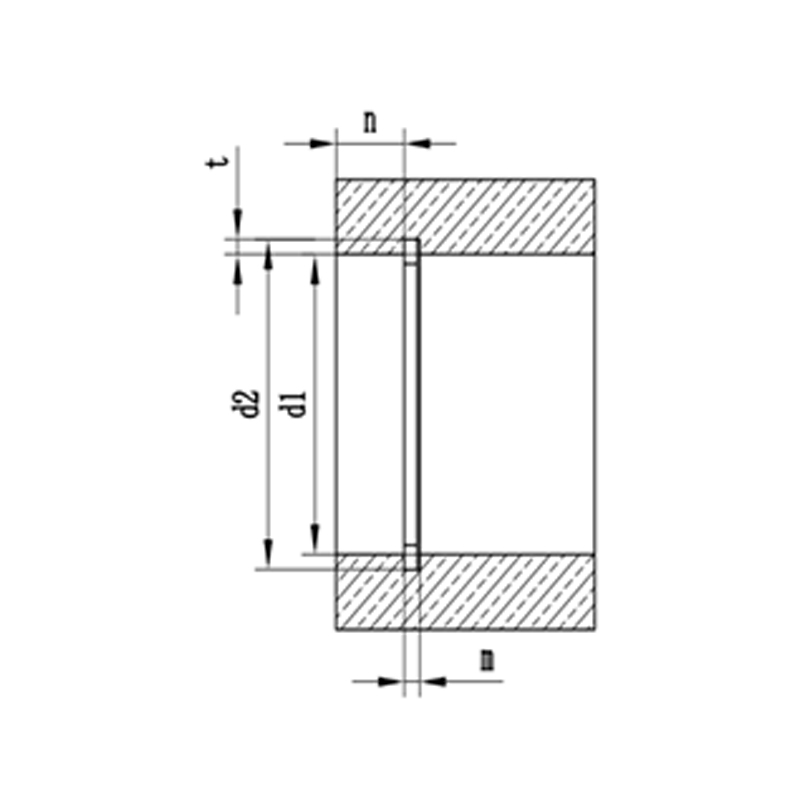

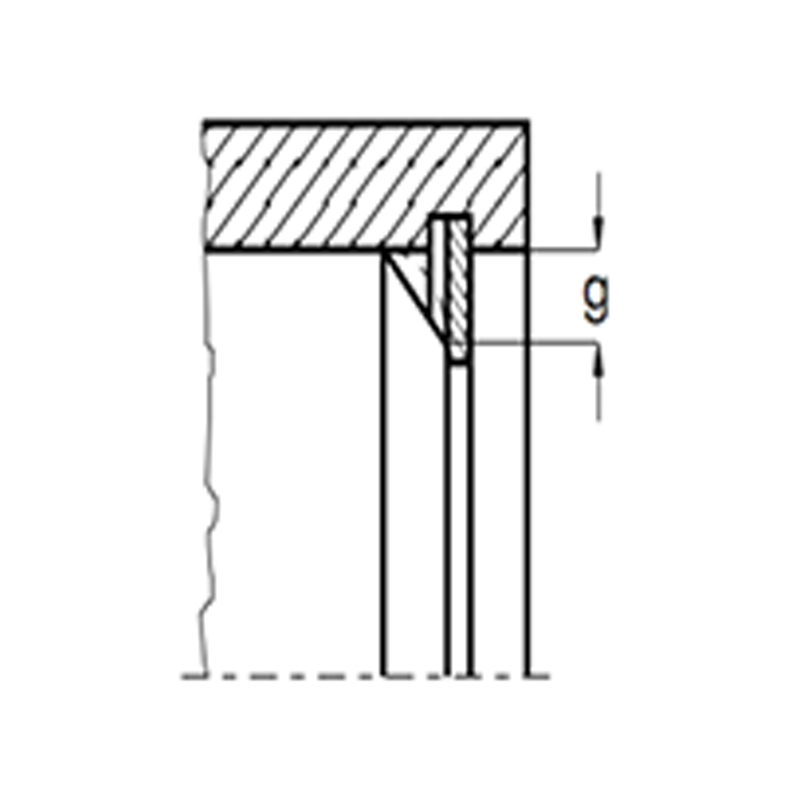

The DIN 472 standard defines the specifications for internal circlips, which are installed in pre-processed grooves within circular holes. These circlips are engineered to provide a secure fit by exerting a controlled radial force against the groove walls. Their primary function is to retain components axially on a shaft or within a bore, preventing unwanted movement during operation.

Unlike external circlips, which are installed on the outer surface of a shaft, DIN 472 internal circlips are designed to fit snugly inside a hole, with their outer diameter slightly larger than the diameter of the assembled circular hole. This interference fit ensures that the circlip remains securely seated, even under dynamic conditions such as shock, vibration, or high-speed rotation.

How Do DIN 472 Circlips Work?

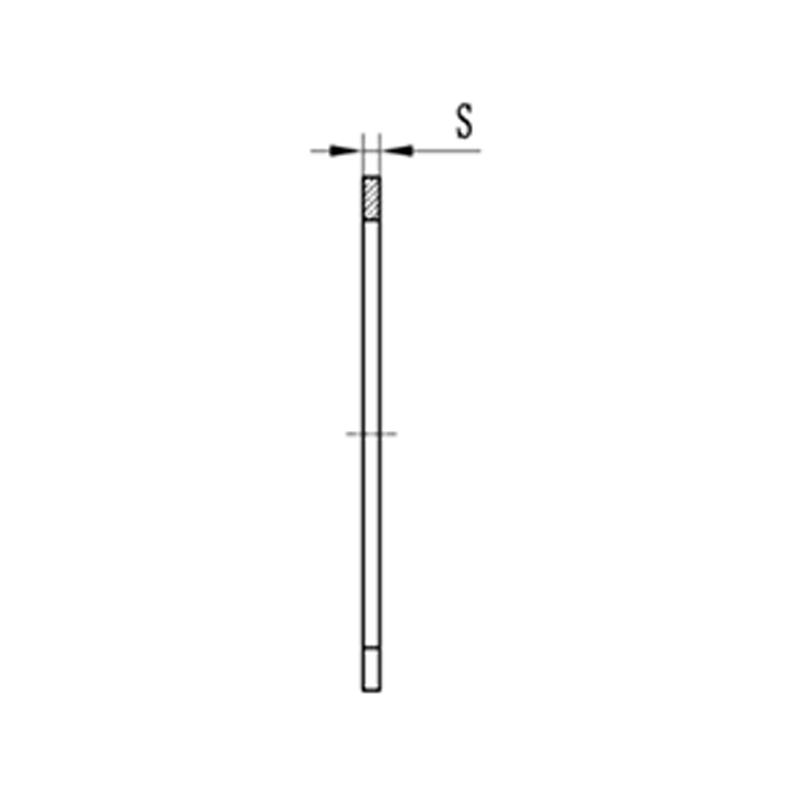

The effectiveness of DIN 472 circlips lies in their design and material properties. Made from high-quality materials such as carbon steel (65Mn, C67S) or stainless steel (304, 2Cr13, 1.4122) , these circlips possess excellent elasticity, strength, and fatigue resistance. When installed using specialized circlip pliers , the circlip expands slightly to fit into the groove and then contracts to its original shape, creating a tight seal that prevents axial displacement.

Key features of DIN 472 circlips include:

Interference Fit : Ensures the circlip remains securely seated in the groove.

Spring Properties : Allows the circlip to absorb shocks and vibrations without permanent deformation.

Precision Dimensions : Tight tolerances ensure consistent performance across various applications.

Applications Across Industries

DIN 472 internal circlips are widely used in applications where axial retention is critical. Some common examples include:

Automotive Industry : In engines, transmissions, and suspension systems, DIN 472 circlips are used to retain components such as bearings, gears, and bushings, ensuring smooth operation under high loads and vibrations.

Aerospace Engineering : In aircraft components like landing gear assemblies and control systems, these circlips provide reliable axial retention while withstanding extreme conditions, including temperature fluctuations and high-frequency vibrations.

Industrial Machinery : From conveyor systems to heavy-duty equipment, DIN 472 circlips are essential for securing rotating or reciprocating parts, reducing downtime and maintenance costs.

Medical Devices : Precision-engineered circlips are used in medical instruments and diagnostic equipment, where accuracy and reliability are non-negotiable.

Material Selection and Surface Treatments

To meet the demands of diverse operating environments, DIN 472 internal circlips are available in a variety of materials and surface treatments.

Common options include:

Carbon Steel : Offers high strength and durability, making it suitable for general-purpose applications.

Stainless Steel : Provides excellent corrosion resistance, ideal for harsh environments such as marine or chemical processing.

Surface Treatments : Options like phosphating , Dacromet , Geomet , galvanizing , and zinc-nickel plating enhance the circlip’s resistance to wear, rust, and environmental degradation.

These material and treatment choices ensure that DIN 472 circlips can perform reliably in virtually any application, whether exposed to moisture, chemicals, or extreme temperatures.

Why Choose Anhui Ningguo Dongbo Fastener Co., Ltd.?

When it comes to sourcing high-quality DIN 472 internal circlips, Anhui Ningguo Dongbo Fastener Co., Ltd. stands out as a trusted partner. Established in September 2005 and located in the Ningguo Economic and Technological Development Zone , Dongbo Fastener has over 46 years of experience in producing retaining rings, washers, elastic cylindrical pins, and other precision-engineered components.

With a focus on innovation and customer satisfaction, Dongbo Fastener offers:

Comprehensive Product Range : From standard DIN 472 circlips to fully customized solutions tailored to specific needs.

Advanced Manufacturing Techniques : Utilizing state-of-the-art equipment and processes to ensure dimensional accuracy and consistency.

Commitment to Quality : Rigorous testing and quality assurance protocols ensure every product meets or exceeds industry standards.

One-Stop Solutions : From mass production to custom development, Dongbo provides integrated manufacturing, R&D, and sales services.