From Carbon Steel to Stainless Steel: Customizable Solutions with DIN984 Retaining Rings

The Importance of DIN984 Retaining Rings

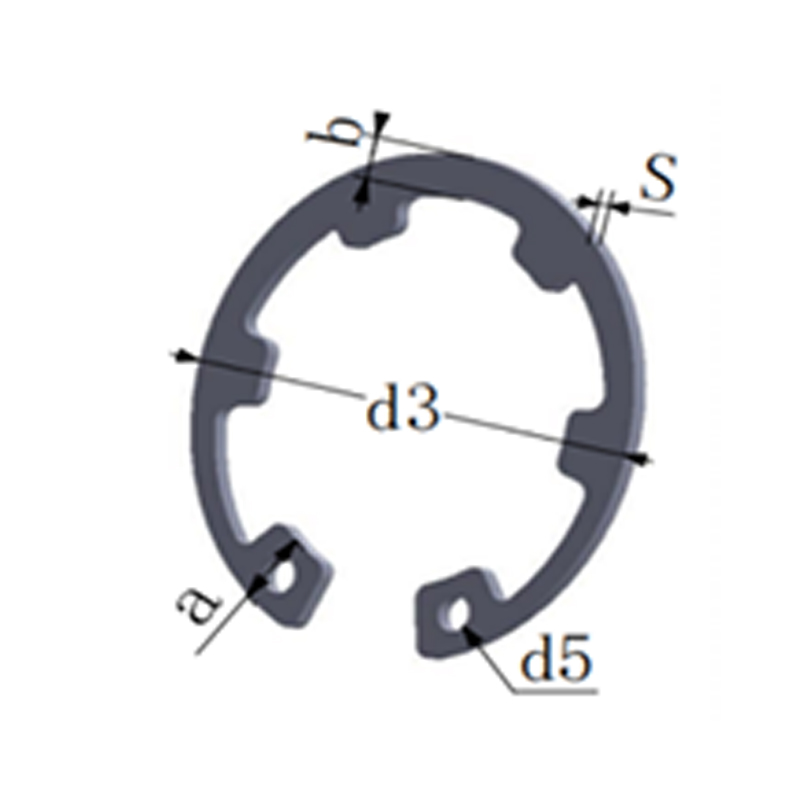

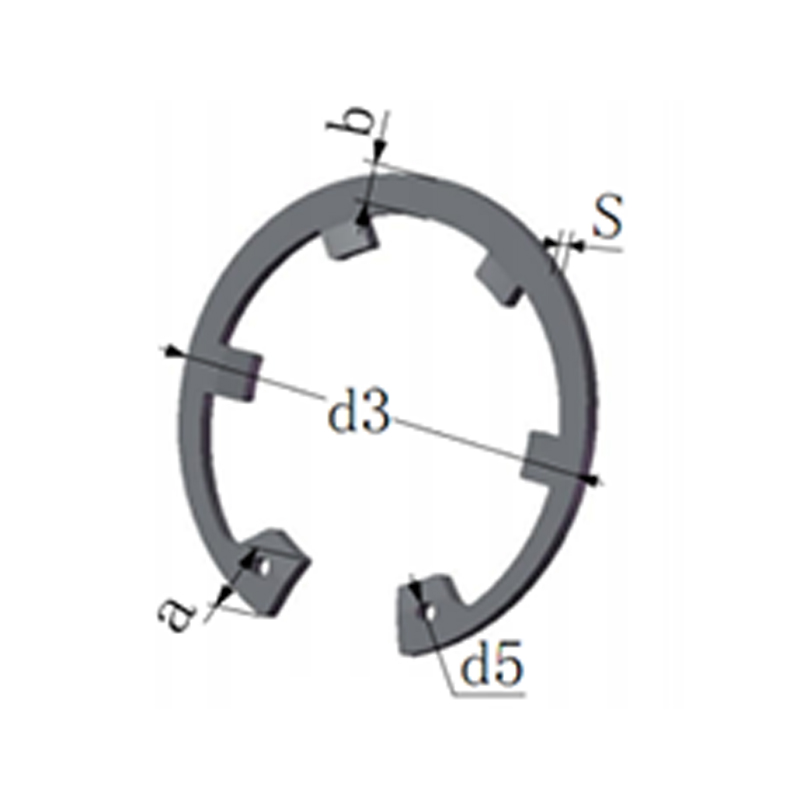

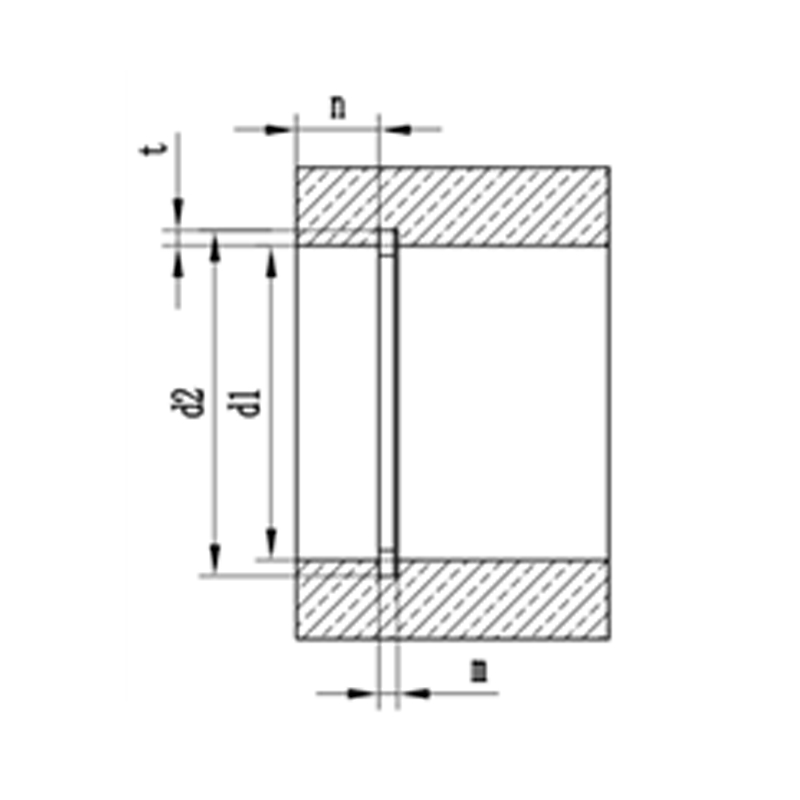

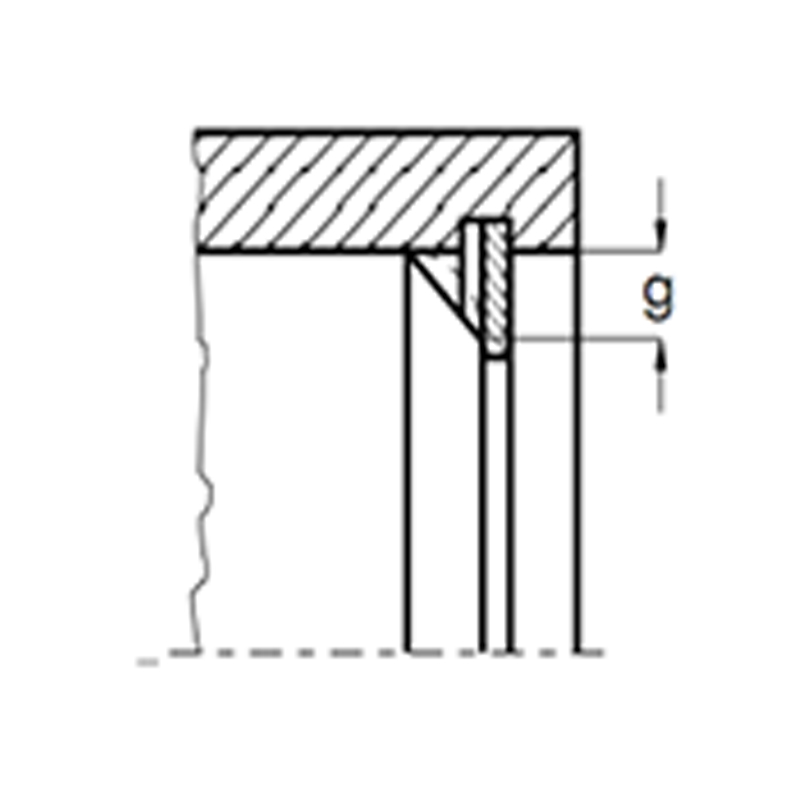

The primary purpose of DIN984 Internal Retaining Rings with Internal Tooth is to prevent axial movement of parts assembled within a hole. These rings feature an internal tooth design that enhances their gripping strength, allowing them to withstand significant impacts while maintaining their position. This makes them indispensable in industries such as automotive, aerospace, and heavy machinery, where precision and durability are non-negotiable.

By securely locking components in place, DIN984 retaining rings reduce wear and tear, minimize downtime, and improve the overall efficiency of mechanical systems. Their ability to handle challenging conditions ensures consistent performance even in the most demanding environments.

Material Flexibility for Every Application

One of the standout advantages of our DIN984 Internal Retaining Rings With Internal Tooth is the variety of materials available, ensuring they can be tailored to suit specific operational requirements. Our material options include:

Carbon Steel: Known for its strength and cost-effectiveness, carbon steel is ideal for general-purpose applications. Variants like 65Mn and C67S provide excellent tensile properties and resilience.

Stainless Steel: For applications exposed to moisture, chemicals, or extreme temperatures, stainless steel options such as 304, 2Cr13, and 1.4122 offer superior corrosion resistance and extended service life.

This flexibility allows customers to choose the perfect material based on factors such as budget, environmental conditions, and performance expectations.

Advanced Surface Treatments for Enhanced Durability

To further optimize the performance of our DIN984 retaining rings, we offer a range of advanced surface treatments. These treatments not only protect the rings from environmental factors but also enhance their appearance and functionality. Options include:

Phosphating: Provides a protective layer that improves lubricity and prevents rusting.

Zinc Plating & Zinc-Nickel Plating: Delivers excellent corrosion resistance, making it suitable for outdoor or marine environments.

Electrophoresis: Ensures a uniform coating that resists chipping and scratching.

Dacromet & Jumet Coatings: Offer unparalleled protection against corrosion, even in highly aggressive conditions.

These treatments ensure that our retaining rings maintain their integrity and performance over time, regardless of the challenges they face.

Why Partner with Anhui Ningguo Dongbo Fastener Co., Ltd.?

Founded in September 2005 and headquartered in the Ningguo Economic and Technological Development Zone , Anhui Ningguo Dongbo Fastener Co., Ltd. has established itself as a leader in the fastener industry. With a team of over 530 employees , a state-of-the-art facility spanning 91 acres , and a rich history of innovation, we are committed to delivering high-quality products that exceed customer expectations.

Our product portfolio includes:

Retaining rings (including DIN984)

Washers (round, butterfly, spherical)

Elastic cylindrical pins

Customized stamping parts

What sets us apart is our ability to provide tailored solutions. Whether you need standard parts for mass production or custom-designed components for specialized applications, we have the expertise and resources to meet your needs.

A Commitment to Innovation and Quality

With 46 years of experience in manufacturing retaining rings and related products, Dongbo Company has built a reputation for excellence. Our dedication to innovation drives us to continuously improve our processes and develop cutting-edge solutions that address evolving market demands.

We combine advanced technology with rigorous quality control measures to ensure that every product meets the highest standards of performance and reliability. By staying true to our core values—innovation, integrity, and customer satisfaction—we have earned the trust of clients across industries worldwide.