Retaining rings are mechanical fasteners used to secure components onto shafts or inside bores by providing axial restraint. They play a critical role in preventing lateral movement of bearings, gears, bushings, and other parts within assemblies. Because retaining rings are often small but highly stressed components, correct selection and application directly influence assembly reliability and service life.

Content

- 1 Functional Purpose of Retaining Rings in Mechanical Assemblies

- 2 Common Types of Retaining Rings and Their Applications

- 3 Material Selection and Performance Characteristics

- 4 Installation Methods and Groove Design Requirements

- 5 Axial Load Capacity and Retaining Ring Performance

- 6 Comparison of Retaining Ring Types

- 7 Maintenance and Inspection Considerations

- 8 Key Factors When Selecting Retaining Rings

Functional Purpose of Retaining Rings in Mechanical Assemblies

The primary function of a retaining ring is to maintain component positioning along an axis without the need for threaded fasteners or additional hardware. Once installed into a groove, the ring applies radial force against the groove wall, creating a secure stop that resists axial loads generated during operation.

Retaining rings are commonly used in compact assemblies where space limitations prevent the use of nuts, bolts, or collars. Their ability to be installed and removed quickly also supports efficient assembly and maintenance processes.

Common Types of Retaining Rings and Their Applications

Retaining rings are categorized based on their installation location and load direction. Selecting the correct type depends on whether the ring is mounted on a shaft or inside a housing bore.

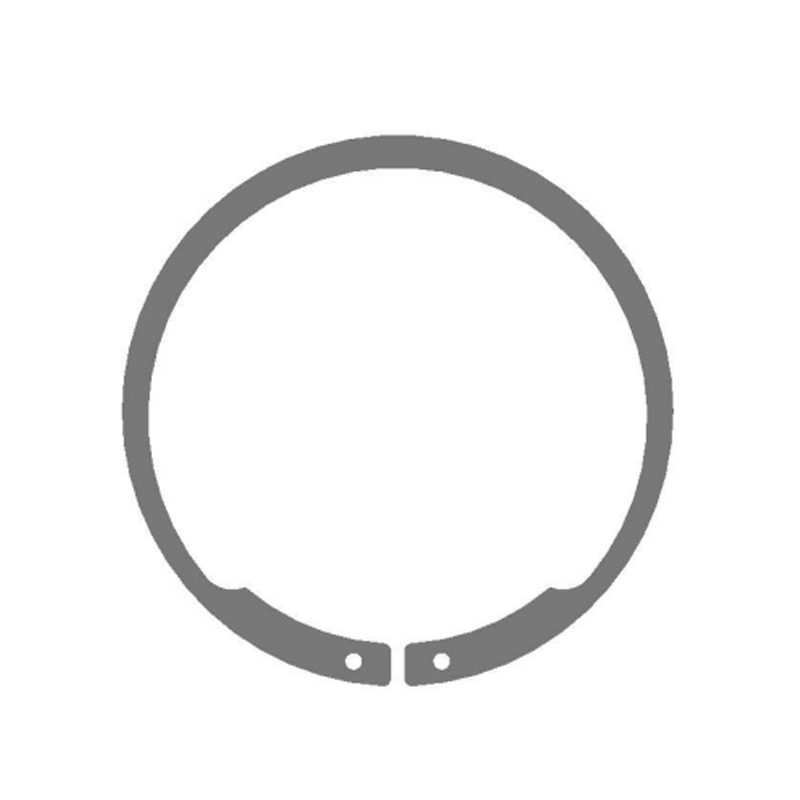

External Retaining Rings for Shafts

External retaining rings are installed onto grooves machined around the outside diameter of a shaft. When seated, the ring applies inward radial force, allowing it to withstand axial loads acting along the shaft. These rings are commonly used to position bearings, pulleys, and gears.

Internal Retaining Rings for Bores

Internal retaining rings are installed inside a groove machined within a bore. They exert outward radial force against the groove wall, preventing components from moving axially within housings or cylinders. These rings are frequently used in gearboxes, hydraulic components, and motor housings.

Material Selection and Performance Characteristics

Retaining rings are typically manufactured from spring steel or stainless steel, allowing them to maintain elastic properties while resisting deformation under load. Material choice affects corrosion resistance, fatigue life, and compatibility with the operating environment.

Key Material Considerations

- Spring steel for high strength and load retention

- Stainless steel for corrosion resistance in humid or chemical environments

- Surface treatments to improve wear resistance and longevity

Installation Methods and Groove Design Requirements

Proper installation of retaining rings depends on accurate groove dimensions and suitable installation tools. Groove width, depth, and edge condition must match the retaining ring specifications to ensure secure seating and consistent load distribution.

Incorrect groove design may lead to insufficient axial load capacity or premature ring failure. Installation tools are often used to expand or compress the ring uniformly, preventing distortion during placement.

Axial Load Capacity and Retaining Ring Performance

The axial load capacity of a retaining ring is influenced by ring thickness, material strength, and groove geometry. Retaining rings are designed to handle specific load ranges, and exceeding these limits may result in ring deformation or dislodgement.

Factors Affecting Load Performance

- Groove edge strength and machining accuracy

- Material elasticity and hardness

- Direction and magnitude of applied axial force

Comparison of Retaining Ring Types

| Ring Type | Installation Location | Primary Use | Load Direction |

| External Ring | Shaft groove | Bearing and gear positioning | Axial along shaft |

| Internal Ring | Bore groove | Housing component retention | Axial within bore |

Maintenance and Inspection Considerations

Although retaining rings are typically low-maintenance components, periodic inspection helps identify wear, corrosion, or loss of elasticity. Rings should be replaced if deformation or surface damage is observed, as compromised retaining rings may no longer provide adequate axial restraint.

Key Factors When Selecting Retaining Rings

Selecting the appropriate retaining ring requires evaluation of shaft or bore dimensions, axial load requirements, operating environment, and assembly constraints. Proper alignment between retaining ring design and application conditions supports stable component positioning and consistent mechanical performance.